- Home

- >

- News

- >

- Industry news

- >

News

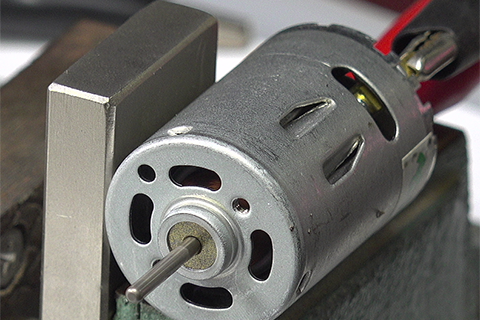

The largest application field of rare earth permanent magnets is permanent magnet motors.

3C consumer electronics products mainly include six categories: mobile phones, tablets, laptops, watches, earphones and wireless charging devices. Taking Apple products as examples are iPhone, iPad, Mac, Watch, AirPods, and MagsafeParts.

Analysis of customs data shows that the volume and price of China's rare earth exports fluctuate, and since 2023, the export tonnage and average price have weakened.

Ferrite magnets has high coercive force Hcb, low recovery magnetic permeability mr, low density (4.5~5.2g/cm3), resistance to oxidation and corrosion, the working part of the demagnetization curve is a straight line, good dynamic characteristics, no need for magnetic stabilization treatment, The material utilization rate is high and the price is cheap. The disadvantage is that the residual magnetism Br is low, the temperature coefficient of magnetic induction is large, the sintered ferrite is hard and fragile, it is difficult to machine, and the resistivity is very large (1012~1014mW.cm), which cannot be cut by wire cutting or EDM. Grinding should be done with a toothless saw or diamond grinder.

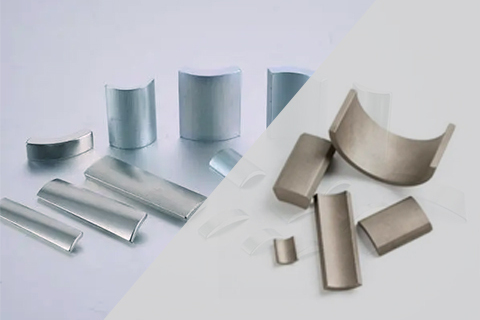

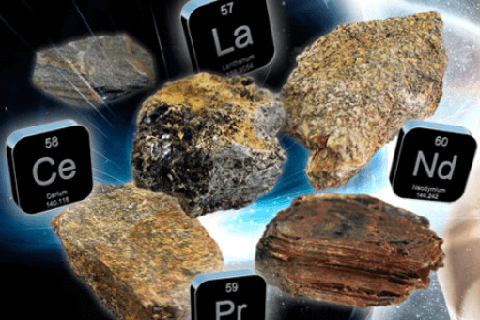

Today we will talk about two common rare earth magnets in magnetic materials - NdFeB magnets and SmCo magnets. They have a wide range of applications in modern industries, but how are they different? Let's find out!

NdFeB magnets, commonly known as neodymium magnets, NdFeB magnets, are made of neodymium, iron, boron and other materials through special processes. The strong magnetic force mainly comes from the intermetallic compound ND2FE14B, because it contains about 30% of rare earth metals Neodymium, so it is also called rare earth permanent magnet. According to different processes, it can be divided into sintered NdFeB permanent magnets and bonded NdFeB permanent magnets.

Neodymium iron boron (NdFeB) permanent magnets are widely used in the motor industry due to their advantages of high coercivity, high residual magnetism, and high magnetic energy product. In this article, we will mainly introduce the knowledge related to permanent magnet motors, hoping to be helpful for you.

Permanent magnet materials are also called "hard magnetic materials". A material that maintains a constant magnetic field once magnetized. It has wide hysteresis loop, high coercive force and high remanence. In practice, permanent magnet materials work in the second quadrant demagnetization part of the hysteresis loop after deep magnetic saturation and magnetization. Commonly used permanent magnet materials are divided into AlNiCo permanent magnet alloy, FeCrCo permanent magnet alloy, permanent magnet ferrite, rare earth permanent magnet material and composite permanent magnet material.

N35 and N52 magnets are two common grades of neodymium magnets. But many people don't know the difference between N35 and N52 magnets. NdFeB magnets are graded by the maximum strength at which they can be magnetized. The higher the value, the stronger the permanent magnet, but the higher the value, the more brittle the magnet becomes.

If you have any doubts or queries with regards to purchasing magnets, this article will be a great help. It delineates the crucial details required to obtain an accurate quotation and delivery. The procurement demands of magnets can generally be divided into two main sections: basic magnet requirements and deadline requirements.

We all know that the speaker in a speaker device is the core part responsible for sound production. The speaker is a transducer that converts electrical signals into sound signals. The performance of the speaker has a big impact on the sound quality.

In the packaging industry, we can often find the application of NdFeB powerful magnets. Magnets play an important role in packaging systems. Packaging manufacturers and designers, as well as marketing agencies, are unanimous in their preference for magnets when packaging their products. The main function of the magnet in the packaging gift box is to seal the package.