How to Effectively Communicate Your Magnet Purchasing Demands?

2023-04-26 13:55If you have any doubts or queries with regards to purchasing magnets, this article will be a great help. It delineates the crucial details required to obtain an accurate quotation and delivery. The procurement demands of magnets can generally be divided into two main sections: basic magnet requirements and deadline requirements.

Basic Magnet Requirements

When we wish to clearly define the purchasing demands of a magnet, several key points need to be addressed: performance requirements, dimensions, magnetization direction, and surface treatment requests. It is essential for the purchasing party to provide a magnet blueprint. In the following example, we will use neodymium permanent magnets.

1. Performance Requirements

The magnet type should be specified. Many suppliers of magnetic equipment have slightly varying performance ranges for the same magnet type. We suggest that both parties clarify the leftover magnetic field Br and intrinsic coercivity Hcj for the corresponding magnet types when communicating magnet type details. (If the purchasing party is not familiar with specific product types, they need to provide auxiliary judgment indicators, such as magnetization intensity, tension, and magnetic flux/magnetic moment). Additionally, based on the magnet's particular working environment, other factors such as residual magnetism and coercivity temperature coefficients can be further clarified.

If there are specific requirements for magnetic flux and other indicators, corresponding detection devices and methods should be defined to determine quality.

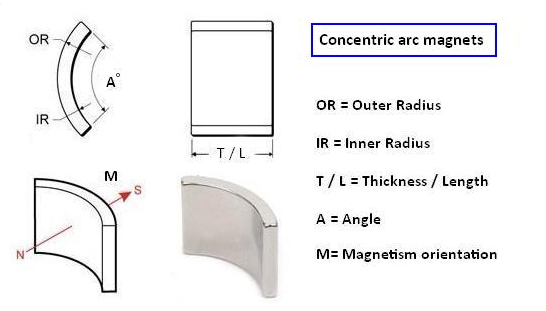

2. Dimensions and Magnetization Direction

When describing purchasing demands, both the magnet's basic shape and size requirements must be clearly defined. For example, for simple products, the basic length, width, and height dimensions, and tolerances should be described. For more complex magnets, additional explanations may be required, including the contour degree and other angle requirements (similar to the 30 degrees±1 degree red mark in the figure below), and it is recommended that the supplier is provided with clear blueprints. Moreover, the magnet should be marked with the product's orientation direction (NS pole) and magnetization method (single-pole or multi-pole), as well as the charging angle, etc.

3. Surface Treatment Requirements

It is necessary for the purchasing party to specify the magnet's surface treatment method, including coating method (plating, chemical plating, electrophoretic deposition, chemical vapor deposition, etc.), coating material (zinc, nickel, copper, aluminum, epoxy resin, etc.), and coating thickness. When it comes to salt spray or other tests, testing conditions should be specified (including setting time and the criterion for testing results).

4. Other Requirements

Appearance requirements, other inspection requirements (such as aging testing, etc.), packaging requirements, and transportation requirements should all be specified.

Product Delivery

Most suppliers have magnet blank inventories and a certain inventory of universal magnet types. Generally, the magnet's shape determines the product's delivery time. Customized products usually require a special mold. If the manufacturer does not have a mold of the required size, the mold-making process can lengthen product delivery time.

Overall, delivery timelines can be compressed, but the ideal timing for the purchasing party may not always be achievable. Orders should be placed in advance for products with urgent timelines.