What is the difference between N35 and N52 NdFeB magnets?

2023-05-04 15:27Neodymium magnets, also known as NdFeB magnets, are tetragonal crystals composed of neodymium, iron, and boron (Nd2Fe14B). This type of magnet is the most commonly used rare-earth magnet and is widely used in electronic products such as hard drives, mobile phones, earphones, battery-operated tools, etc. N35 and N52 magnets are two common grades of neodymium magnets. But many people don't know the difference between N35 and N52 magnets. NdFeB magnets are graded by the maximum strength at which they can be magnetized. The higher the value, the stronger the permanent magnet, but the higher the value, the more brittle the magnet becomes.

What is N35 magnet?

N35 magnets refer to sintered NdFeB magnets. In KOE, the intrinsic coercive force is 33-36MGOE. The conversion of MGOe and kA/m3 is 1MGOe=8kA/m3. The maximum energy product of N35 NdFeB material is 270kA/m3 .

What is N52 magnet?

N52 is a much higher grade with a maximum energy product of 48-51MGOE. The conversion between MGOe and kA/m3 is 1MGOe=8kA/m3, and the maximum magnetic energy product of N52 NdFeB material is 400kA/m3;

What is the difference between N35 and N52 magnets?

Under the premise of the same specifications, the magnetic attraction force of N52 is much greater than that of N35.

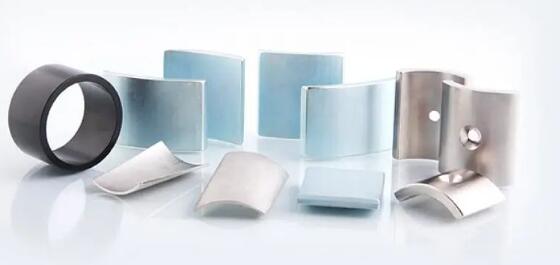

NdFeB powerful magnets are generally divided into N35/N38/N40/N42/N45/N48/N50/N52 and other grades. The most obvious difference between the various performance classes is the difference in magnetic properties. For example, for products of the same specification, the higher the performance level, the better the magnetic performance of the product. However, NdFeB strong magnet is a surface molecule and its active product. Therefore, the surface of NdFeB strong magnets must be electroplated, such as galvanized, nickel-plated, nickel-plated copper-nickel, epoxy resin, etc.

The N52 grade magnets are the highest grade of permanent neodymium magnets on the market. All N52 neodymium magnets offer the same 52 MGOe (matter of science) as high energy rare earth magnets, regardless of their size or shape, or a flux density of 1.44 Tesla (matter of science). Of course, the actual holding force increases with magnet size. In comparison, grade 52 magnet neodymium super magnets are 14% stronger than N45 neodymium magnets and 60% stronger than other neodymium magnets when they are the same shape and size.

N52 grade neodymium magnets are expertly designed and crafted to tight tolerances and strong performance. N52 grade rare earth magnets are more powerful than N35 grade magnets of the same size.

What is the difference between N35 magnet and N35H magnet?

N35 magnets and N35H magnets actually have similar magnetic properties, which is what we call pulling force. There are only two biggest differences. First, N35H is a high-temperature resistant grade with a temperature resistance limit of 120 degrees Celsius. N35 is an ordinary grade with a maximum working temperature not exceeding 80 degrees Celsius. Second, the price difference is very large, and the price of raw materials for high temperature resistant grades is much higher than that of ordinary N35 grades.

NdFeB magnet is a high-performance magnetic material widely used in electronics, medical, aerospace and other fields. However, as the temperature increases, the magnetic properties of this magnet will also decrease to varying degrees. According to statistics, for every increase of 1 degree Celsius, the magnetic properties of neodymium magnets will decrease by 0.11%. This is a small loss, but it can be fully recovered on cooling as long as the maximum operating temperature is not exceeded.

What is the high temperature resistance of neodymium iron boron?

In the theoretical experimental environment, the upper limit of the maximum operating temperature of the neodymium magnet is 80 degrees Celsius, and the Curie temperature is 310 degrees Celsius. High-performance high-temperature-resistant grade NdFeB has a maximum working temperature upper limit of 230 degrees Celsius. This temperature is the test result of the experimental environment. Due to different high-temperature environments in actual applications, the actual maximum operating temperature may be lower than the theoretical maximum operating temperature.

What is the maximum temperature resistance of each grade of NdFeB?

NdFeB magnets are actually divided into many grades. The common brand N series has a maximum temperature resistance of 80 degrees Celsius. M series, high temperature resistance up to 100 degrees Celsius. H series, the maximum temperature resistance is 120 degrees Celsius. SH series, the maximum temperature resistance is 150 degrees Celsius. UH series, the maximum temperature resistance is 180 degrees Celsius. EH series, the maximum temperature resistance is 200 degrees Celsius. AH series, the maximum temperature resistance is 230 degrees Celsius.

What are the application fields of different grades of sintered NdFeB magnets?

N and M grades are mainly used in medical magnets, electroacoustics, home appliances, voice coil motors, electronic products and other fields.

H grades are mainly used in the field of motors and sensors.

Due to its high intrinsic coercive force, SH grade is mostly used in wind turbines, industrial motors and other places that require high magnetic properties.

UH grades are mostly used in automotive motors and air-conditioning compressors.

The EH grade with the best magnetic properties is widely used in fields such as hybrid electric vehicles, electromagnetic valves and sensors.