What are the coatings of NdFeB magnets? What are the functions of each coating?

1. What is magnet coating?

Magnet coatings are used to reduce the susceptibility of magnets to corrosion and other negative environmental factors that can degrade the magnets. Strong magnet coatings are similar to ordinary paint except that tiny particles of iron powder are mixed in. Rare earth magnetic coating materials include nickel, copper, chromium, gold, black zinc, epoxy resin, etc. The magnet coating is very thin, so it has almost no effect on the magnetic properties of the magnet itself.

2. Why and when do magnets need coating?

The surface treatment of NdFeB magnets is not to improve its performance, and the surface coating of NdFeB magnets is mainly for protection. NdFeB powerful magnets without surface coating are easy to react with oxygen in the air and oxidize rapidly, so in order to prevent this from happening, we usually carry out electroplating treatment. Moreover, the appearance of the powerful magnet after electroplating is more beautiful.

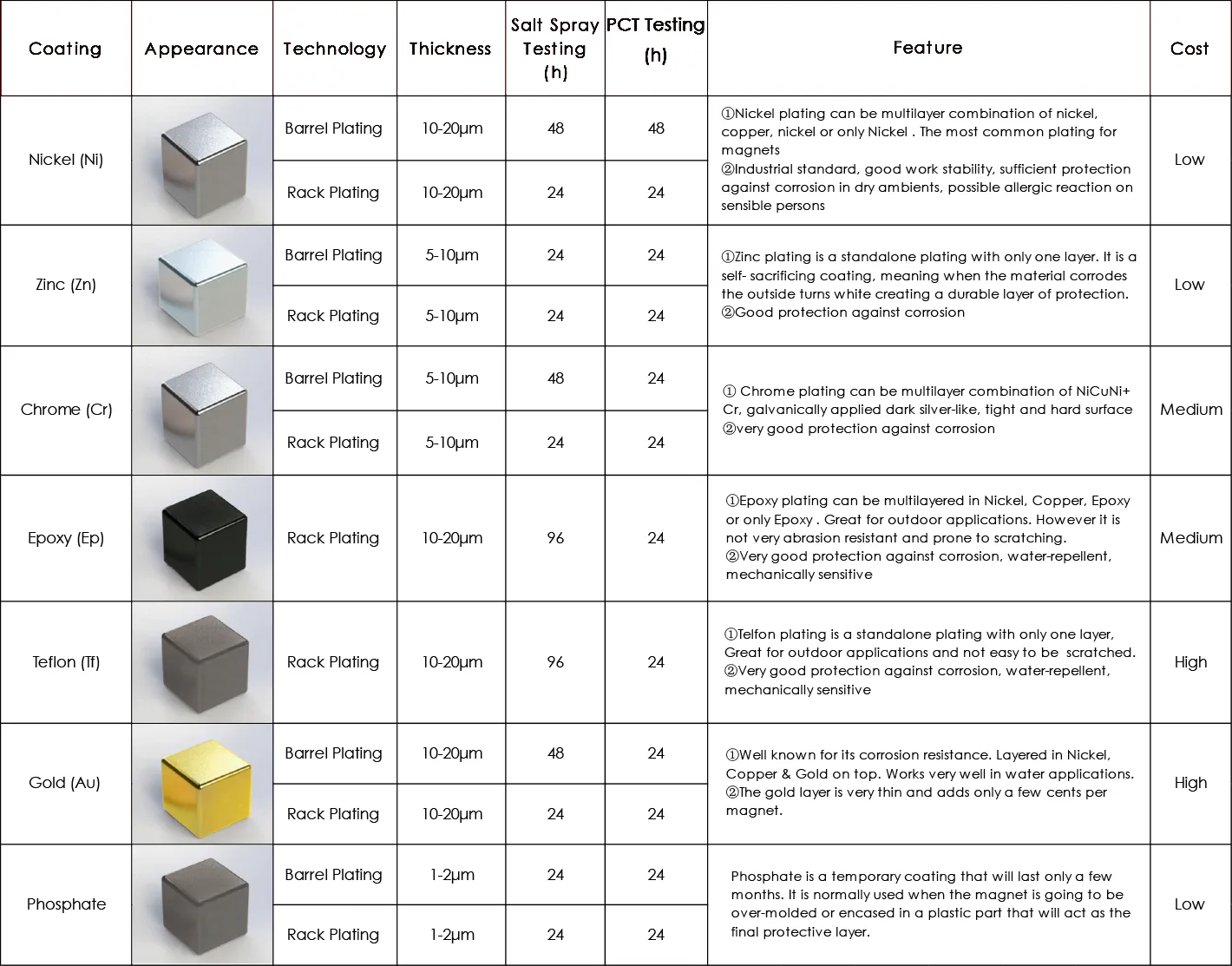

3. What are the common magnet coatings on the market?

There are many different magnet coatings for sintered neodymium magnets, but the appropriate coating will depend on the parameters of the application, as well as many other factors such as environment, temperature, durability, and many others.

Common coatings:

Nickel

Nickel is the most common coating on powerful magnets. Now generally three layers are plated, namely nickel-copper-nickel. It protects rare earth magnets from chipping and corrosion in ambient air. However, it cannot be used as a protective coating against moisture, water or salt water. Nickel coating is also a decorative finish with a bright appearance similar to the color of stainless steel. It has a thickness of 15-25 um and an operating temperature of approximately 200°C.

The main fields of application of nickel-plated NdFeB magnet coating are electrical motors, medical devices, generators, pumps, sensors, automobiles, etc., as well as several other industries.

Zinc

The zinc coating provides good adhesion, you can keep an eye out for the magnets in the motor, many are galvanized, it is used to protect the magnets from corrosion in the surrounding air and to provide mild protection from moisture, water or salt water . However, if the magnet is in a wet environment, it is not a suitable choice. It has a thickness of 4-10 um and a maximum operating temperature of approximately 120°C. Zinc coatings are mostly used in low temperature applications and where a little protective barrier is desired.

Epoxy resin

Unlike gold, zinc and nickel, epoxy magnet coatings act as an excellent barrier to salt, ambient air, water or moisture. But it's slightly more expensive than the first three alternatives. Although it scratches easily and is 15-30 um thick, it has good adhesion to steel with magnetic glue. Epoxy coatings are mainly used in the marine, electrical motor, sensor, automotive and consumer goods industries.

Gilded

A gold-plated coating is used as an FDA-approved medical coating for in vivo use, and it is used as an undercoat for Ni-Cu-Ni. Like the nickel coating, it helps protect the magnet from corrosion in the ambient air, but can also provide mild protection against moisture, water or salt water. Gold is thin (about 0.1-1um) so it may perform poorly in salt spray testing, as most gold coatings are meant to be thin. Its maximum operating temperature is approximately 200°C.

Injection molding/plastic

This coating requires molds and tools. It is an excellent protective coating for rare earth magnets against breakage, impact and corrosion. It can be used for coating of medium and large magnets. Note that the small magnets cannot be coated with plastic. They act as a good protective coating against salt water, humidity or water.

Plastic can be dyed almost any color. The usual thickness of the coating is between 1 and 2 mm. The maximum operating temperature generally depends on the type of ABS plastic selected. It is used in healthcare, education, consumer products, and more.

Summarize

The coating of NdFeB powerful magnets has two main functions: to protect the magnets and to have a beautiful appearance. However, the magnetic properties of the magnet cannot be changed, and the durability will be improved. Common coatings: nickel plating, galvanization, gold plating, epoxy resin, injection molding/plastics, and of course other coatings, we will gradually introduce you to them later.