What is the pulling force of a magnet?

Each magnet has a pulling force. Magnets made of different materials have different pulling forces. The pulling force value can tell you how strong the magnet is. The pulling force is measured in pounds or kilograms. It is the magnet from 1/8 inch (3.175 mm). Thick steel plates pull directly on the required force, and the pull force also tells you the limit of the magnet's holding power.

In general, any magnet with a pulling force greater than 7 pounds (3.175 kg) may pinch fingers. Stronger magnets may be more dangerous and are best handled by experienced personnel.

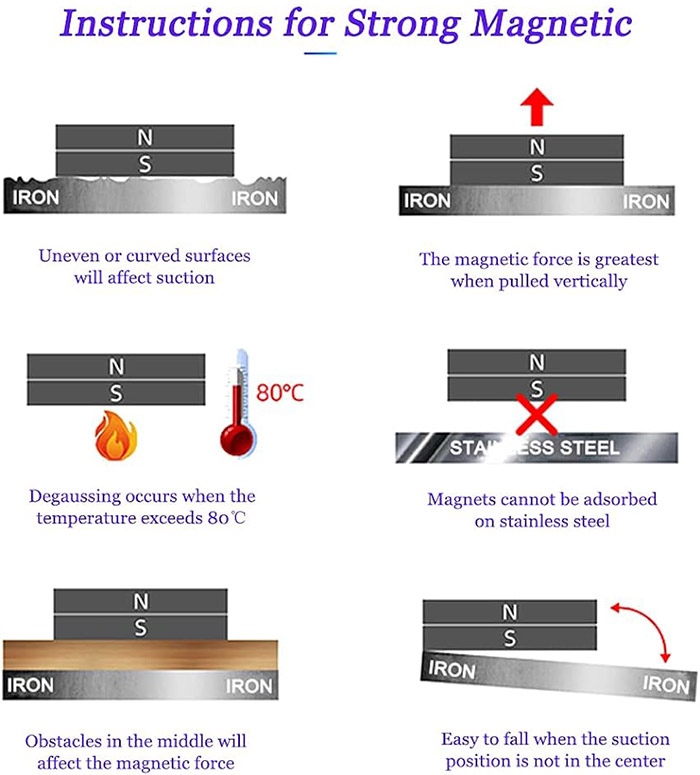

The placement of the magnet greatly affects the pulling force;

While a fixed value for pull force allows you to calibrate how much weight or tension the magnet will hold, how it is placed also has an impact.

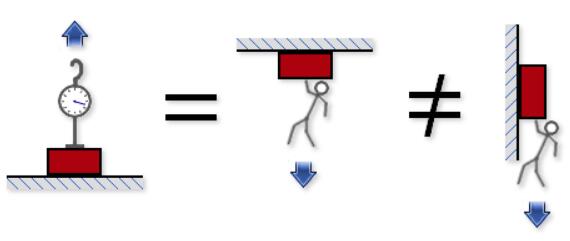

Magnets placed vertically (such as on a steel beam or the underside of a table) will maintain the listed pull weight.

Magnets placed horizontally on the side of a refrigerator or filing cabinet will only withstand 30% or less of the listed pull force due to gravity and the possibility of the magnet slipping onto the surface of the attachment.

Likewise, magnets stick best to ferromagnetic surfaces and not to chrome, brass, aluminum, silver, gold, wood, plastic, or ceramic tiles

Magnet pulling force, also called magnetic pulling force, is a measure of magnet magnetic field strength. It is mainly divided into vertical pulling force and horizontal pulling force.

The main differences between the vertical pulling force and the horizontal pulling force of the magnet are as follows;

1. The vertical pulling force refers to the attraction or attraction force of the magnet in the vertical direction, and the horizontal pulling force refers to the attraction force of the magnet in the horizontal direction.

2. In the absence of external force, the maximum vertical pulling force of the magnet is greater than the maximum horizontal pulling force, because gravity enhances the vertical attraction.

3. The vertical pulling force attenuates rapidly as the distance between the magnet and the adsorbent increases, but the horizontal pulling force attenuates slowly.

4. The vertical pulling force depends more on the magnetic properties of the magnet itself, while the horizontal pulling force is not only related to the magnetic properties, but also related to the magnetic circuit design.

5. The horizontal pulling force can continue to transmit motion through the mechanism design, but the vertical pulling force can only produce static suction.

6. In the motion system, vertical suction is often used to obtain fastening, and then the movement is transmitted through horizontal pulling force.

7. Measuring vertical tension is simple, but measuring horizontal tension requires special equipment or conditions.

8. In terms of use, the two are more synergistic than antagonistic.

Is the vertical pulling force greater or the horizontal pulling force greater?

When a magnet attracts an object, the magnitude of the vertical pulling force and the horizontal pulling force depends on many factors, including the magnetic strength of the magnet, the strength of the external magnetic field, the nature of the object being adsorbed, the distance between the magnet and the object, etc. Therefore, it cannot simply be determined that the vertical pulling force must be greater than the horizontal pulling force, or vice versa.

Generally speaking, at the same distance, the maximum vertical suction force of a magnet can reach 3-5 times the maximum horizontal suction force. Therefore, the difference between the two should be considered during mechanical design and the magnetic characteristics of the magnet should be rationally applied.

The pulling force of a magnet is usually measured using a pull gauge, which is a very subjective measurement method that is usually not accurate and will be affected by many external factors.

1. The material of the object being attracted

2. The size of the attracted object

3. The configuration of magnets to objects

4. Surface condition and finish

5. Load direction

6. Working temperature