What are the classification and characteristics of permanent magnet ferrite for motors?

2023-06-02 15:19Ferrite magnets has high coercive force Hcb, low recovery magnetic permeability mr, low density (4.5~5.2g/cm3), resistance to oxidation and corrosion, the working part of the demagnetization curve is a straight line, good dynamic characteristics, no need for magnetic stabilization treatment, The material utilization rate is high and the price is cheap. The disadvantage is that the residual magnetism Br is low, the temperature coefficient of magnetic induction is large, the sintered ferrite is hard and fragile, it is difficult to machine, and the resistivity is very large (1012~1014mW.cm), which cannot be cut by wire cutting or EDM. Grinding should be done with a toothless saw or diamond grinder.

Ferrite has two series: Isotropy and Anisotropy. According to different molding process, anisotropic ferrite has dry pressing (Dry-Molding) and wet pressing (Wet-Molding). points. Classified according to the main components, there are two commonly used barium ferrite (Barium Ferrite) and strontium ferrite (Strontium Ferrite).

Ferrite powder can be made into various plastic ferrite without mixing with rubber or plastic. In order to distinguish it from sintered ferrite (Sintered Ferrite), this type of ferrite is called bonded ferrite (Bonded Ferrite)

Wet pressing and dry pressing

The production process of sintered ferrite (Sintered Ferrite) is usually to pre-sinter (about 1300°C) the raw materials into permanent magnet rough products after proportioning the raw materials. The pre-fired crude product has poor performance and is unstable, and needs to be ball-milled again into a powder with a size below a single domain, molded under a sufficiently strong external magnetic field, and finally sintered for a short time (1200°C~1280°C).

In the ferrite magnetic field forming process, wet pressing is to place the slurry after the secondary ball milling directly in the mold, and apply a certain direction (consistent with the magnetic field direction required for the product) at the same time during the press forming. Magnetic field, so that the easy magnetization axes of the single-domain grains are aligned along the direction of the external magnetic field. At the same time, the pump should be used to remove water when pressing, and the upper and lower punches need gaskets to prevent the slurry from being drawn out, and then dry after forming.

Due to the high moisture content of the slurry in wet pressing molding, the crystal grains can rotate freely during the molding process, which is convenient for grain orientation, so the magnetic properties are good, and the Br is large and the Hcb is high. However, gaskets and suction filtration are required during molding, and the production efficiency is low. Dry pressing molding is to add an appropriate amount of binder (Binder) to the dry powder without moisture after the second ball milling, and place it in a molding magnetic field for pressure molding. The magnetic field orientation of dry pressing is slightly worse, and the magnetic properties are worse than wet pressing.

Barium Ferrite and Strontium Ferrite

Barium ferrite is a permanent magnet ferrite with a large amount of use and a wide range of uses. The ideal composition ratio is BaO.6Fe2O3 (or BaFe12O19). The actual permanent magnet product produced is BaO.(5~6)Fe2O3, the anisotropy constant is K13.3X105J/m3 at room temperature, and it has better coercive force after being made into single-domain particles.

The ideal composition ratio of strontium ferrite is SrO.6Fe2O3, and the actual permanent magnet product produced is SrO.(5~6)Fe2O3. Its single domain critical size is larger than that of barium ferrite, and it is easy to obtain single domain during sintering. The anisotropy constant K13.7X105J/m3 is larger than barium ferrite, and its anisotropy is better, so the performance is better than barium ferrite, Br and Hcb are higher than barium ferrite, and it is not easy to cause irreversible demagnetization at low temperature, so it is more suitable for Occasions subject to greater demagnetization.

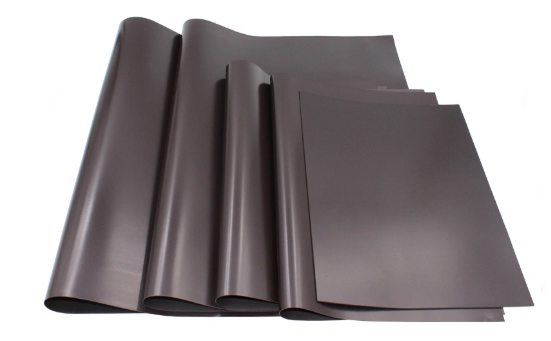

Bonded ferrite-rubber magnet

Ferrite powder is not mixed with rubber or plastic to make composite permanent magnet material bonded ferrite, which can be molded or injected to make various high-precision and complex-shaped components. Bonded ferrite is divided into soft bonding (rubber bonding) and hard bonding (plastic bonding). The soft bonding product is a rubber magnet, which can be pressed into a sheet or a strip.

In addition to its extremely easy-to-process mechanical properties, bonded ferrite has another advantage of being able to produce a magnetic energy product of any size from the maximum value to zero, and has good temperature stability, good corrosion resistance, and high coercive force. . Shape plasticity, low cost and wide performance range make bonded ferrite the fastest growing hotspot in the permanent magnet material market. Since bonded ferrite is filled with a large amount of non-magnetic binder with a volume of 10%~15%, the magnetic properties are usually lower than similar sintered ferrite.