- Home

- >

- News

- >

- Industry news

- >

News

Before the invention of rare earth permanent magnet materials in the 1970s, AlNiCo alloys had always been the permanent magnet materials with the strongest magnetic properties. However, because the composition contained strategic metals cobalt and nickel, the cost was high. With the ferrite permanent magnets and With the advent of rare earth permanent magnets, AlNiCo materials have been gradually replaced in many applications. However, in some high-temperature applications and situations with high magnetic stability requirements, AlNiCo magnets still occupy an unshakable position.

On October 13, the General Administration of Customs announced import and export data for September.

NdFeB magnet is a permanent magnet material with high magnetic energy product, high coercivity and high magnetization intensity. It is composed of elements such as neodymium (Nd), iron (Fe) and boron (B). It has attracted much attention due to its excellent magnetic properties and has broad application prospects.

Magnetic materials are magnetically ordered materials that have ferromagnetic or ferrimagnetic properties and have practical application value. A fundamental difference between them and other materials is that they are sensitive to external magnetic fields. Broadly defined magnetic materials also include antiferromagnetic materials and other weakly magnetic materials that have practical or possible application value.

Magnetic materials are divided into two categories: isotropic magnets and anisotropic magnets: Isotropic magnets have the same magnetic properties in any direction and can be magnetized arbitrarily; Anisotropic magnets have different magnetic properties in different directions, and the direction in which the best magnetic properties can be obtained is called the orientation direction of the magnet.

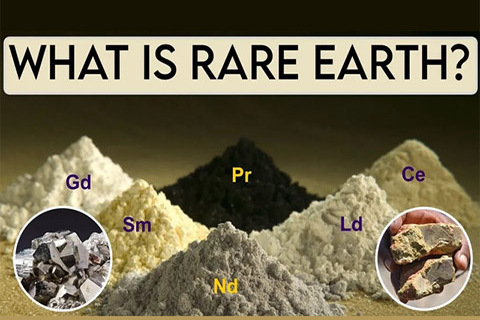

The analysis of customs statistics shows that in the first seven months of 2023, China's rare earth exports will continue to grow, while the monthly export volume will fluctuate significantly due to events.

NdFeB is a common permanent magnet material, which is popular for its strong magnetism, high performance and wide application. However, in the process of use, some matters need to be paid attention to in order to give full play to its functions and ensure safety. This article will introduce some precautions during the use of neodymium magnets.

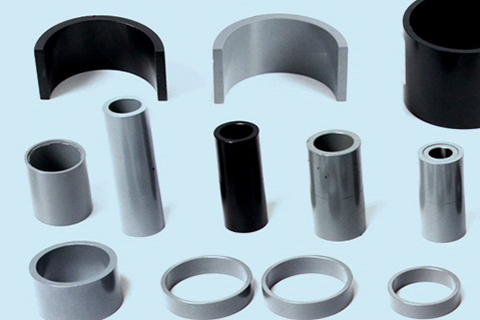

The main shapes of sintered NdFeB magnet products include squares, cylinders, rings, tiles, sectors and various special-shaped products. In actual production, large blanks are produced first, and then processed according to the size requirements of users to obtain the final finished product

Many friends may have such a question, do magnets with the same performance and volume have the same suction force? It is said on the Internet that the suction force of an NdFeB magnet is 640 times its own weight. Is this credible?

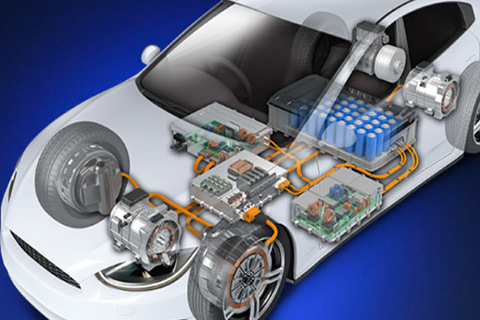

NdFeB magnet is a high-performance permanent magnet material, which is widely used in various fields, such as new energy vehicles, green energy, microelectronic equipment, etc. In recent years, with the development of the global economy and the advancement of technology, the demand for NdFeB magnets has continued to grow, and the price has also fluctuated. This article will analyze the price trend in recent years to provide reference for industry professionals.

In the first half of 2023, the price trend of the domestic light rare earth market fell sharply. The price of neodymium oxide market at the beginning of the year was 770,000 yuan/ton, and the market price in the middle of the year was 477,500 yuan/ton, with a half-year price drop of 37.99%...

Generally, the practitioners of NdFeB magnet manufacturers have the most contact with sintered NdFeB magnets, that is, sintered magnets. According to different production processes, there are injection-molded NdFeB magnets in the classification of NdFeB products, What are the differences between injection molded NdFeB magnets and sintered NdFeB magnets?