Do magnets with the same performance and volume have the same suction force?

2023-07-21 14:37Many friends may have such a question, do magnets with the same performance and volume have the same suction force? It is said on the Internet that the suction force of an NdFeB magnet is 640 times its own weight. Is this credible?

In fact, this question can be diverged, that is, what factors are related to the attraction of the magnet. First of all, it needs to be clear that magnets only have adsorption force for ferromagnetic materials. There are only three kinds of ferromagnetic materials at room temperature, that is, iron, cobalt, nickel and their alloys, and they have no adsorption force for non-ferromagnetic materials.

Some formulas for calculating suction can be found on the Internet:

F=k*B²*S/2

F=0.577*S*B²

Are these formulas accurate? The answer is inaccurate, but the trend is no problem. The magnitude of the magnet's suction is related to the magnetic field strength and the adsorption area. The greater the magnetic field strength, the larger the adsorption area and the greater the suction.

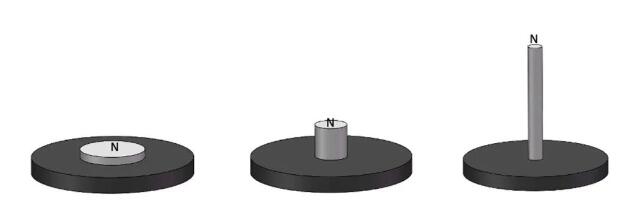

Then the next question is, are the magnets of the same volume, which are flat, cylindrical, and elongated, have the same suction force? If not, which has the most suction?

First of all, it is certain that the suction power is not the same. Which kind of suction is the largest we need to relate to the definition of the maximum magnetic energy product. When the working point of the magnet is near the maximum magnetic energy product, the magnet has the maximum working energy. The adsorption force of the magnet is also a manifestation of work, so the corresponding suction force is also the largest. It should be noted here that the attracted object needs to be large enough to completely cover the size of the magnetic pole, so that the material, size, shape and other factors of the attracted object can be ignored.

How to judge whether the working point of the magnet is at the point of maximum magnetic energy accumulation. When the magnet is in the state of direct adsorption with the attracted material, its adsorption force is determined by the air gap magnetic field and the size of the adsorption area. Taking a cylindrical magnet as an example, when H/D≈0.6, its center Pc≈1, and the attraction force is the largest when it is near the working point of the maximum magnetic energy product. This is also in line with the law that magnets are usually designed to be relatively flat as adsorbents. Taking the N35 D10*6 magnet as an example, through FEA simulation, it can be calculated that the suction force of the iron plate is about 27N, almost reaching the maximum value of a magnet with the same volume, which is 780 times its own weight.

The square magnet is similar to the circular magnet. When it is directly adsorbed to the attracted material, the center Pc≈1, that is, it is near the working point of the maximum magnetic energy product, and the suction force will reach the maximum value of the magnet with the same volume, such as 10*10*6.5 or 15*10*8.

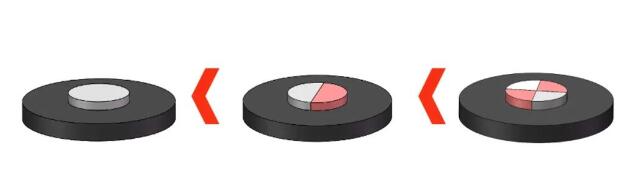

Of course, the above is only the adsorption state of the single pole of the magnet. If it is multi-pole magnetization, the suction force will be completely different.

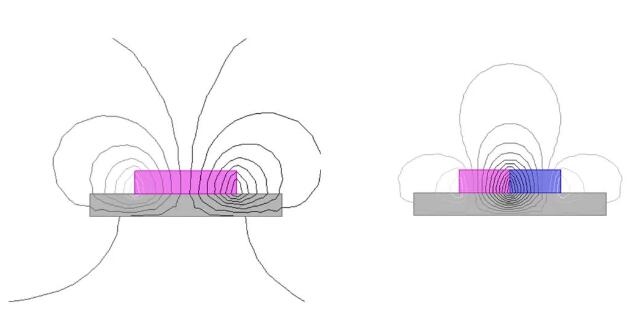

Why does the suction force change so much after a magnet of the same volume is made into multi-pole magnetization? The reason is that the adsorption area S remains unchanged, and the value of the magnetic flux density B passing through the attracted object increases a lot. It can be seen from the magnetic force line diagram below that the density of the magnetic force lines passing through the iron sheet increases significantly for the multi-pole magnetized magnet. Still take the N35 D10*6 magnet as an example, it is made of bipolar magnetization, and the suction force of the FEA simulation adsorption iron plate is about 1100 times of its own weight.

After the magnet is made into multi-pole magnetization, each pole is equivalent to a more slender magnet, and its Pc value has changed, so it can no longer be calculated according to the Pc value of the overall size, so its optimal size is no longer H/D≈0.6, but a flatter magnet. The specific size is related to the multi-pole magnetization method and the number of poles.