- Home

- >

News

If you have any doubts or queries with regards to purchasing magnets, this article will be a great help. It delineates the crucial details required to obtain an accurate quotation and delivery. The procurement demands of magnets can generally be divided into two main sections: basic magnet requirements and deadline requirements.

In the packaging industry, we can often find the application of NdFeB powerful magnets. Magnets play an important role in packaging systems. Packaging manufacturers and designers, as well as marketing agencies, are unanimous in their preference for magnets when packaging their products. The main function of the magnet in the packaging gift box is to seal the package.

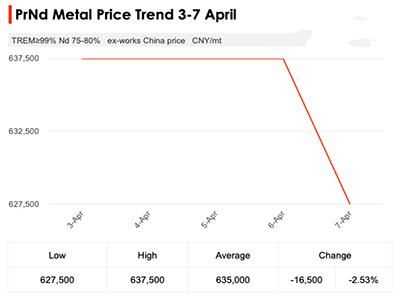

Last week, the price of light rare earth parts in China has declined and the sales on the floor and downstream purchase are not so bad. It is expected that the price trend will decline in the later stage.

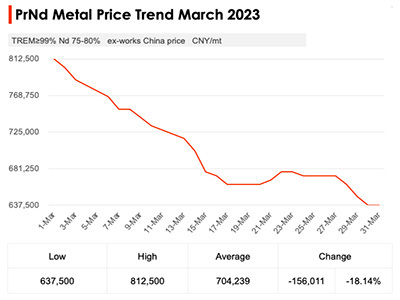

According to the business community monitoring shows that the rare earth market price index fell sharply in March, the domestic rare earth market trend continues to decline.

Do you want to know which is the biggest supplier of permanent magnets in China? Do you want to know which is the leading manufacturer of rare earth NdFeb? Are you looking for permanent magnets products? This article provides you with a list of famous magnet suppliers in China for your reference.

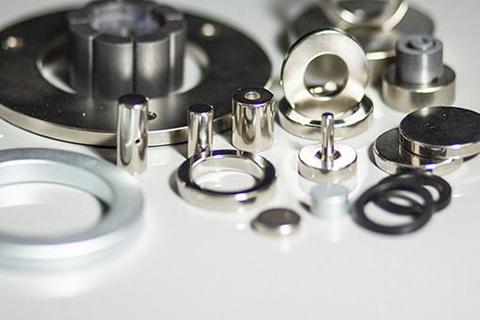

Magnetic materials are materials that can react to magnetic fields in a certain way. According to the degree of magnetization, they can be divided into permanent magnet materials and soft magnetic materials. Permanent magnet materials, also known as hard magnetic materials, are mainly characterized by their high magnetic property and high coercivity. After removing the external magnetic field, they can still maintain high magnetism for a long time. Common permanent magnet materials are divided into aluminum-nickel-cobalt permanent magnet alloy, fe-chrome-cobalt permanent magnet alloy, permanent magnet ferrite, rare earth permanent magnet material and composite permanent magnet material, etc.

Rare earth is widely used and continues to expand. Rare earth plays an important role in improving product performance, upgrading product structure and transforming to clean energy. It is not only involved in traditional fields such as agricultural light textile, metallurgical industry, petrochemical industry, glass and ceramics, but also key materials in emerging industries such as production of special light sources and related equipment, national defense and military, and intelligent manufacturing.

Rare earth permanent magnet materials are used in various micro motors in computer, automobile, instruments, meters, household appliances and other industries, as well as nuclear magnetic resonance equipment, electrical parts, magnetic separation equipment, magnetic machinery, magnetic therapy equipment and other components that need to generate strong gap magnetic field.

The production process of rare earth permanent magnet materials is a constantly evolving process. In the early production process, metallurgy was the main method. Rare earth elements were extracted by high-temperature smelting, and then magnetic materials with strong magnetic properties were prepared by chemical reduction and vacuum smelting. The process of this method is complicated, the production cost is high, and there is a risk of environmental pollution.