Neodymium Disc Countersunk Hole Magnets

The countersunk hole allows straightforward attachment to almost any material such as wood, plastic and masonry, to name just a few. Simple to attach with a flat head screw, the tapering screw head sits flush inside the countersunk magnet for seamless professional finish. These magnets can also be recessed into timber or plastic and secured with a countersunk screw for a permanent result without the need to use messy glue. Glue can perish or discolour with age however screws stay true, making them the ultimate fixing solution.

- Information

Manufacturer supply super strong neodymium magnet round neodymium disc countersunk magnets

Neodymium magnet is available in a wide range shape and dimension. A neodymium countersunk magnet is a functional type of magnet ring with one end surface show as a standard ring, but the other end surface has an angled countersunk hole. It is normally measured by the outer diameter, through hole diameter, major diameter, depth, and angle. The angle generally being 90 degrees. Its countersunk hole provides a convenient way to fix the magnets onto both magnetic and non-magnetic surface securely using a matching standard countersunk screw. Almost entirely of Neodymium countersunk magnets are magnetized along its axial axis. In addition, countersunk hole is also available in Neodymium block magnet and Neodymium arc magnet.

Products description

Product Name | Neodymium Magnet |

Material | Permanent Magnet |

Size | Custom made any size |

Shape | Disc, Block, Cylinder, Ring, Rod, Arc,Segment, Cube,Sphere etc |

Grade | N35-N52,(M,H,SH,UH,EH,AH) |

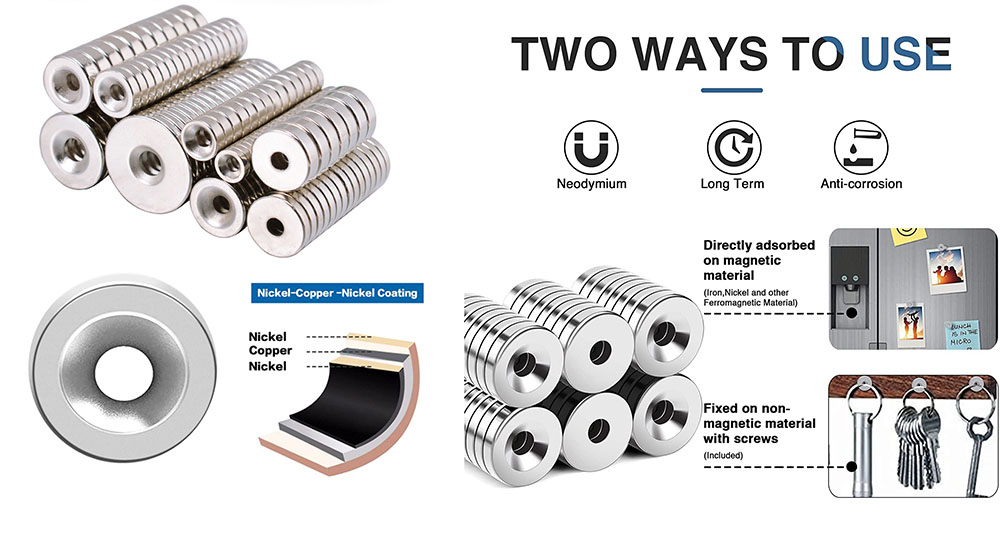

Coating | NiCuNi, Zinc , Epoxy etc |

Features

Very Durable - Coated with three layers of nickel, copper and nickel to reduce corrosion and provide a smooth finish which greatly increase the longevity of the Magnets.

Practical Innovative Design- The ring magnets with holes are easy to mount with screws. They don't fall off. The heavy duty rare earth magnets can directly absorbed on magnetic material or can be fixed on non-magnetic material with screws(Included). Two ways to use to meet your various needs

Small Useful Magnetic Tools- The little neodymium countersunk magnets can be used as tool storage, whiteboard magnets, manual DIY, wardrobe door suction, refrigerator magnets, locker suction or used for scientific purposes, arts and crafts or school classroom or perfect for cabinet doors or glued to plastic drill bit cases and stuck on the side of you drill press.

Note:

Since neodymium magnets are very powerful, they may pinch you and are capable of causing serious injuries. Please wear a pair of thick gloves and eye protection when handling.

All magnets are brittle and may chip or shatter if they are allowed to collide together or onto a steel surface. In order to prevent injuries and broken magnets, please keep magnets at least 2 feet apart from each other or magnetic items

Neodymium magnets are capable of causing injury if mishandled. Please keep all magnets away from children for their safety, and away from pacemakers and other electronics that may be sensitive to magnets.

Neodymium magnets are not toys. Neodymium magnets should be handled with care and they should NOT be handled by children.

FAQ:

Q1. Why are most neodymium magnets plated or coated?

A1. Neodymium magnets are composed mainly of Neodymium, Iron, and Boron. If neodymium magnets are not plated, the iron in the material will oxidize very easily if exposed to moisture. Even normal humidity will rust the iron over time. To protect the iron from exposure to moisture, most neodymium magnets are plated or coated.

Q2. What is the thickness of the nickel (Ni-Cu-Ni) plating?

A2. The nickel plating is actually triple plating of nickel-copper-nickel. The layers are Ni: 5-6μm, Cu: 7-8μm, Ni: 5-6μm, for a total thickness of 17-20μm.

Q3. What happens when magnets get wet?

A3. Water does not significantly affect a magnet's strength except that small parts of some magnets may have a chemical reaction with water, so that some magnets have to be coated if they will be immersed in water for an extended period of time.

Q4. Are magnets waterproof?

A4. No. While magnets are typically coated with nickel, zinc or epoxy to protect them against rust and corrosion from moisture – they are not waterproof. Neodymium magnets will work submerged, soaked or underwater for a short period. ... These magnets are encased in a waterproof PVC pouch that protects them from moisture.

Q5. What is a cup magnet?

A5. Cup magnets are magnets inset into steel cups that assist in mounting and increase their holding force. They are commonly used in holding applications where they are attached to a surface with a countersunk screw.