Magnetic Properties of Alnico Magnets

Alnico magnets, composed of primarily aluminum (Al), nickel (Ni), and cobalt (Co). This class of magnet remains a preferred material because of its excellent temperature stability, high magnetic flux density, and resistance to corrosion.

Alnico magnets are manufactured through a casting or sintering process. The casting process allows the magnet to be manufactured into intricate and complex shapes. Sintered Alnico is made from a powdered mixture of ingredients that are pressed into a die under tons of pressure. The Sintering process allows for the magnets to be manufactured to tighter tolerances and higher mechanical strength.

The most common Alnico cast magnets are in grades 2, 3, 5 and 8. They are best suited for applications exposed to operating temperatures above 400 ° Fahrenheit. They maintain approximately 85% of their room-temperature strength up to 1000 ° F. They become completely demagnetized at approximately 1600 °F. For best results with Alnico 5 magnets, the length should be no less than 5 times the cross-section diameter or the diameter of a circle equal in area to the cross-section.

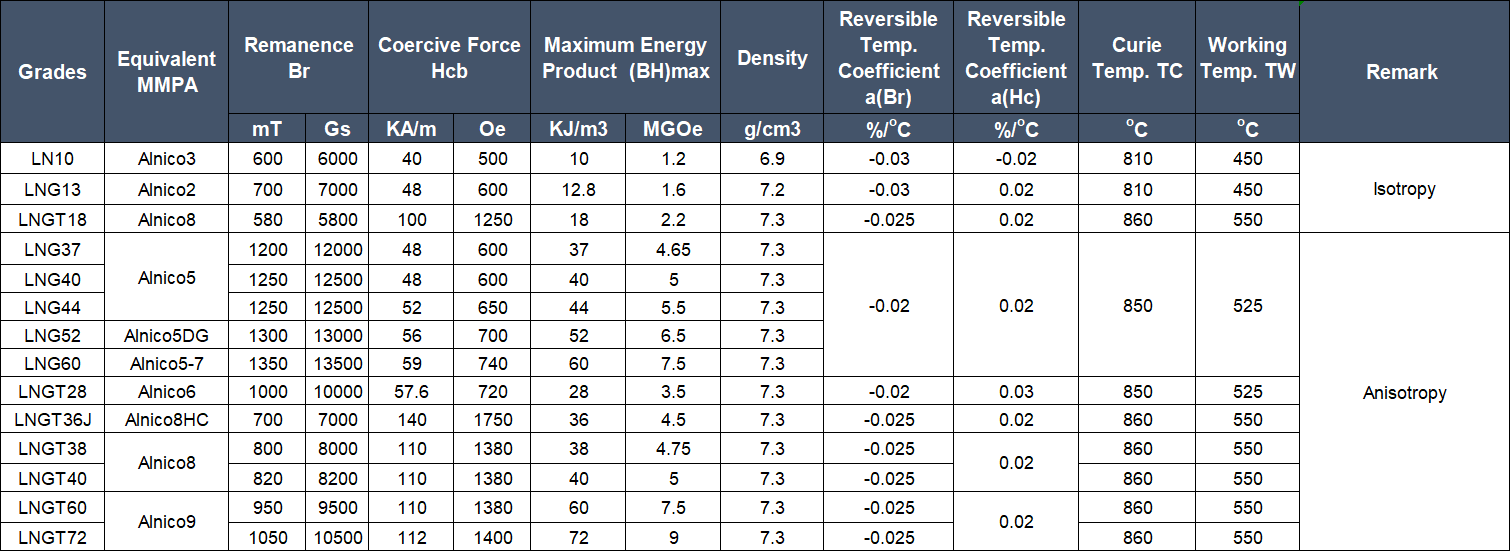

TableⅠ:Cast Alnico Properties

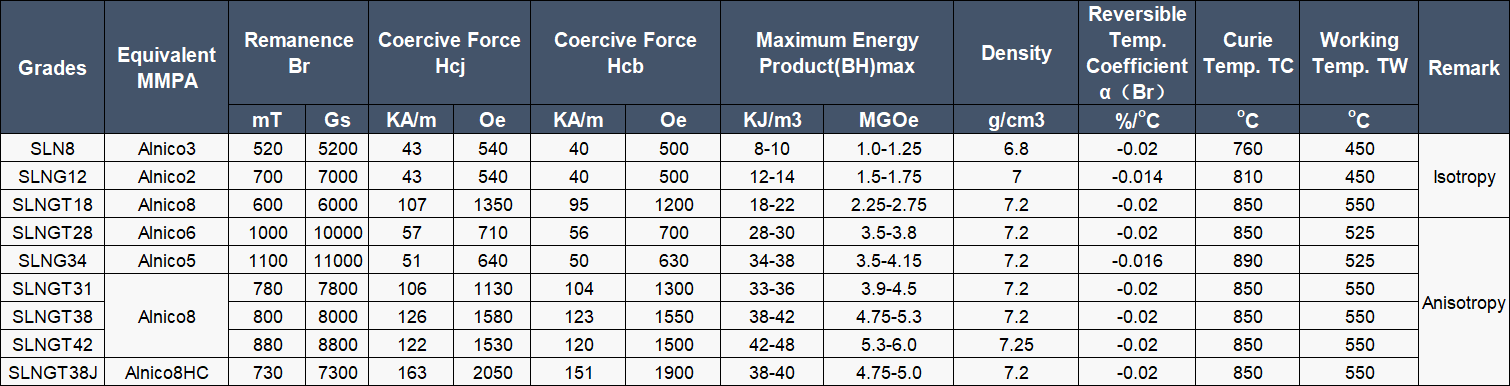

Table Ⅱ:Sintered Alnico Properties

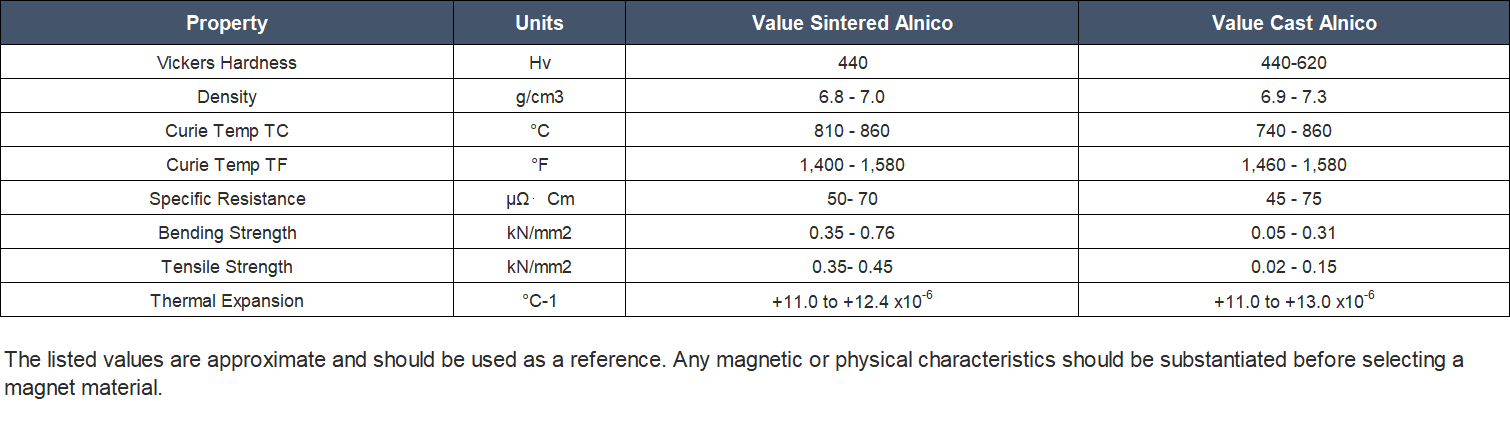

Table Ⅲ:Alnico Magnets - Physical Properties

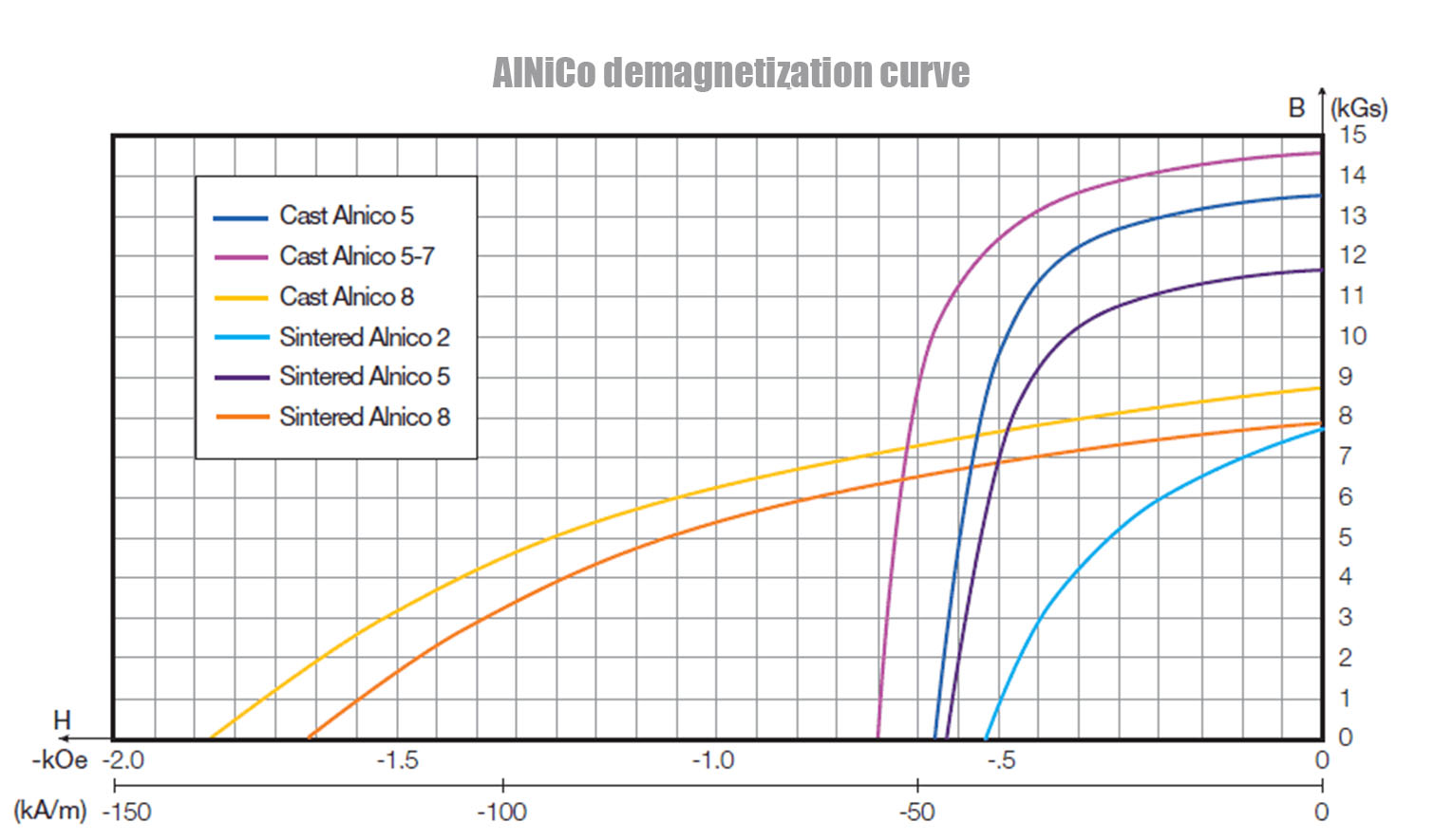

Table Ⅳ:AlNiCo demagnetization curve