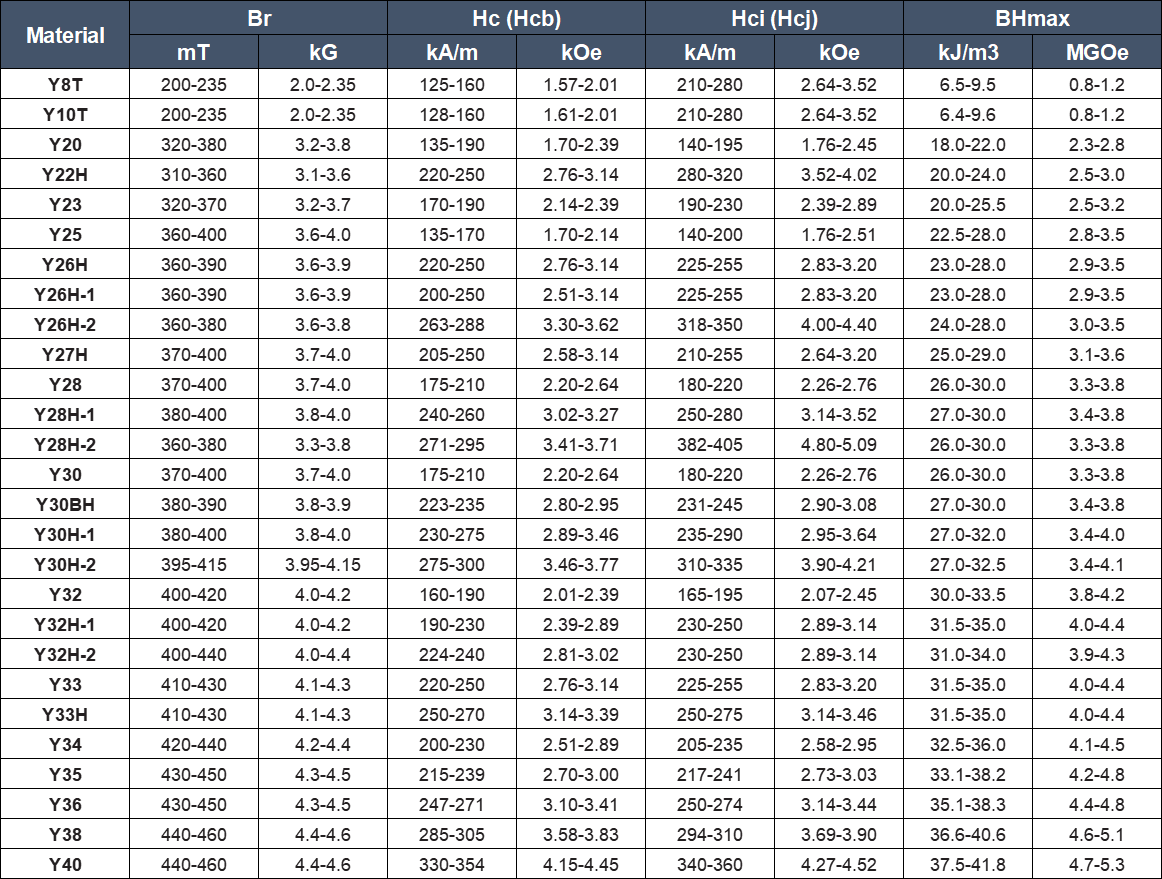

Magnetic Properties of Ferrite Ceramic Magnets

Ferrite Magnets, termed Hard ferrites, are not the same as soft ferrites as would be used in transformers.

The Chinese ferrite magnet nomenclature system has a structure to it. Y is an identifier for Ceramic Magnet / Hard Ferrite Magnet. The number following it is linked to the BHmax Energy product. Any letter after the number is an additional grade identifier. There are 27 grades of ferrite magnet.

Anisotropic grades (direction of magnetisation locked in structure) are stronger than isotropic grades.

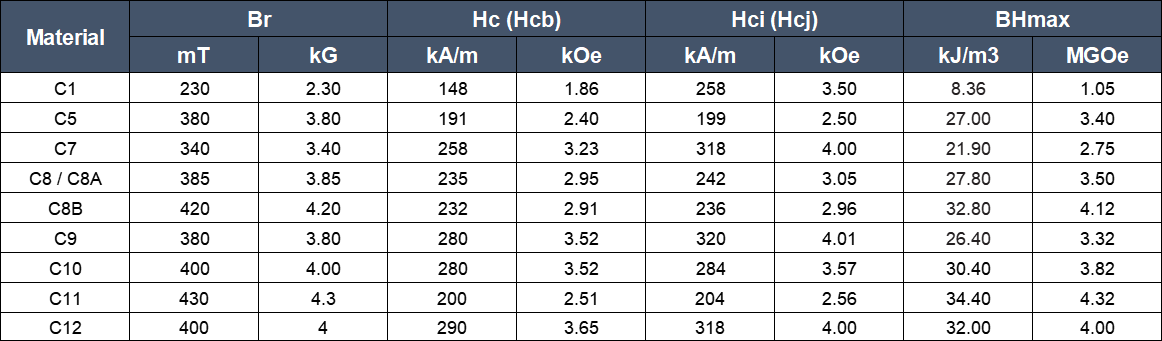

Isotropic (unoriented) grade example:− C1; Anisotropic (oriented) grade examples:− C5, C7, C8.

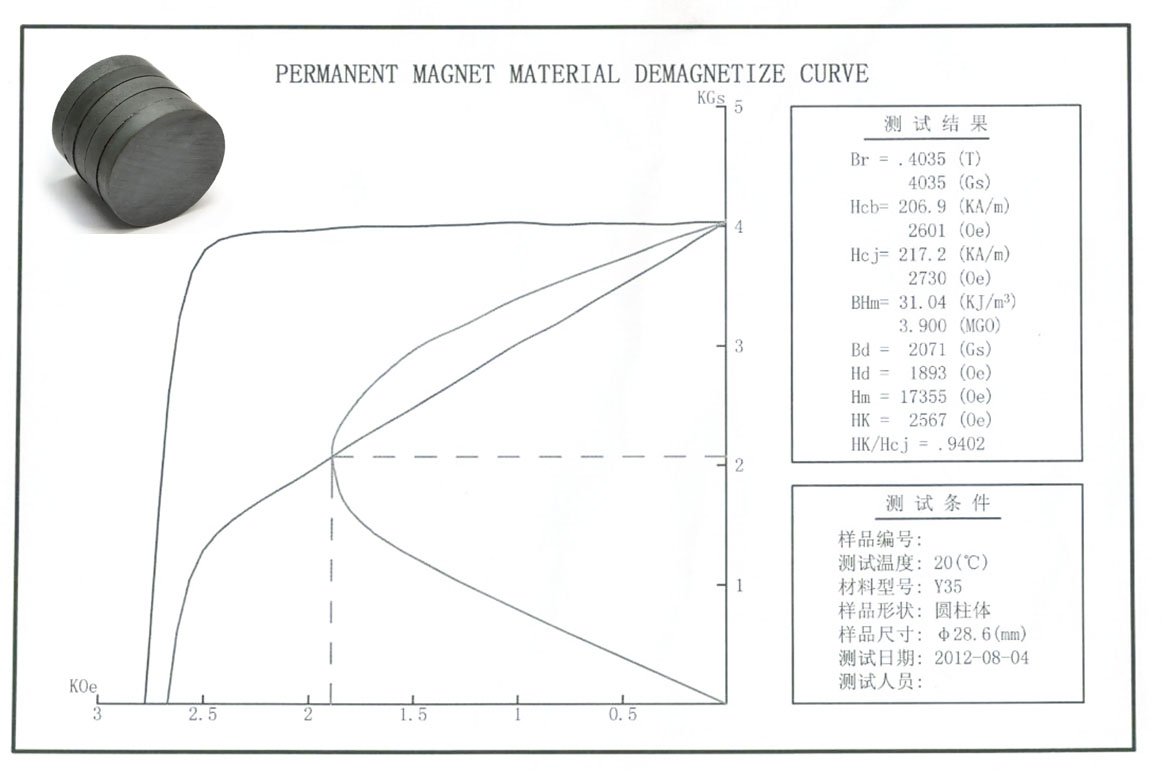

Below is an example BH curve for Ferrite C5 (Y30). Ferrite C5 and Ferrite C8 are the most popular grades of hard ferrite (ceramic) magnets.

TableⅠ: Ferrite (Ceramic) Magnet grades

Chinese Standard – Commonly used globally, especially in UK and EU

Typical Values

American Standard (still in use but limited range)

Typical Range of Values

Quick Cross Reference Guide

C5 = Feroba2 = Fer2 = Y30 = HF26/18

C8/C8A = Feroba3 = Fer3 = Y30H−1.

C1 = Y10T / Y8T

C7 = Y26H−2

C8B = Y33

C9 = Y30H−2

C10 = Y33H

C11 = Y34

C12 = Y30H−2.

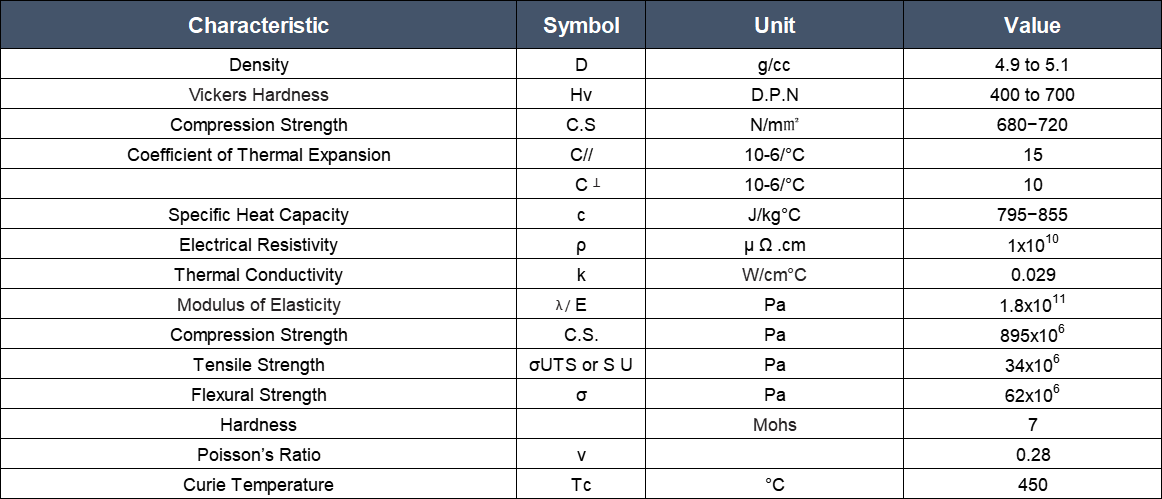

TableⅡ: Physical Characteristics (Typical)

Table Ⅲ: Ferrite demagnetization curve

Tolerances

Tolerances:−+/−3% is common. +/−0.25mm is also commonly used. The tolerance available will depend on the size and shape of the magnet.

Maximum and Minimum Working Temperature

(Please note − your application will affect the performance available).

The maximum recommended operating temperature is +250 to +300 degrees C.

The minimum operating temperature varies with the magnet shape and magnetic circuit. It could be as low as −60 degrees C but may be as high as 0 (zero) degrees C.