Super strong neodymium ring magnets

We accept customized services:

1.Shape and Dimension Requirement

2.Material and coating requirements

3. Processing according to design drawings

4.Requirements for Magnetization Direction

5. Magnet Grade Requirements

6. Surface treatment requirements (plating requirements)

Please contact us and we will be happy to provide pricing for any magnet you may need.

- Information

N52 wholesale custom permanent neodymium ring magnet manufacturer

NdFeB magnet is an alloy magnet made from Nd,Fe,B and other metal elements,which has the high remanence,high coercive force,high energy and high performance/cost ratio. We have a huge range of Ring magnets in sizes and materials to suit every application. Neodymium Rings are available in grades (strengths) from powerful N52 grade right down to N30 grade. Magnetic grades for Neodymium magnets allow the same size magnet to have a stronger pull force. We also have rare earth Ring magnets suitable for high temperature operating environments up to 180℃.

Coating options for the Neodymium Ring magnets include Nickel, Plastic, Epoxy and Gold.

Product Description

| Product name | Super Strong Neodynium Magnet Ring Magnets | |

| Material | Sintered Neodymium-Iron-Boron ( NdFeB ) | |

Grade & working Temperature | Grade | Max. Operating Temperatures |

| N35-N52 | 80°C (176°F) | |

| 35M- 54M | 100°C (212°F) | |

| 35H-52H | 120°C (248°F) | |

| 35SH-50SH | 150°C (302°F) | |

| 28UH-48UH | 180°C (356°F) | |

| 28EH-45EH | 200°C (392°F) | |

| 28AH-42AH | 230°C (428°F) | |

| Size | Customized size | |

| Shape | Customized (block,Disc,Cylinder, Bar, Ring,Arc,Countersunk) | |

| Coating | Customized (Ni, Zn, Epoxy, Gold, etc.) | |

| Size tolerance | ±0.05mm for diamater /thickness, ±0.1mm for width/ length | |

| Density | 7.5-7.6g/cm³ | |

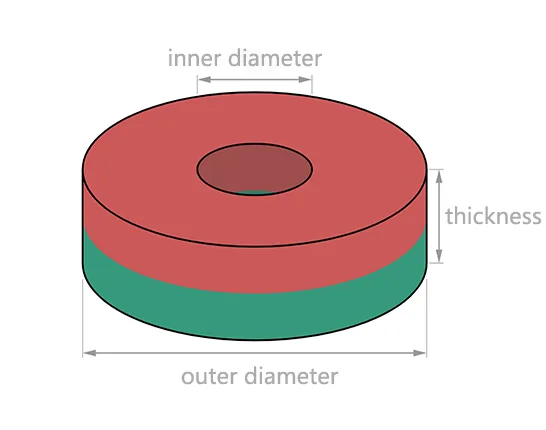

| Magnetization | Thickness Magnetized, Axially Magnetized,Diametrally Magnetized | |

| Feature | Strong magnetic power, high magnetic grade, high working temperature, exact dimension, tiny machining tolerances, small and special shapes, vairious coating for anti-corrosion. | |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators,printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. | |

Products Details

1.Material The raw materials are Nd, Fe and B. Starting from the selection of materials, high-quality neodymium-iron-boron magnets are produced with high-quality rare-earth materials and various mixed materials. |  |

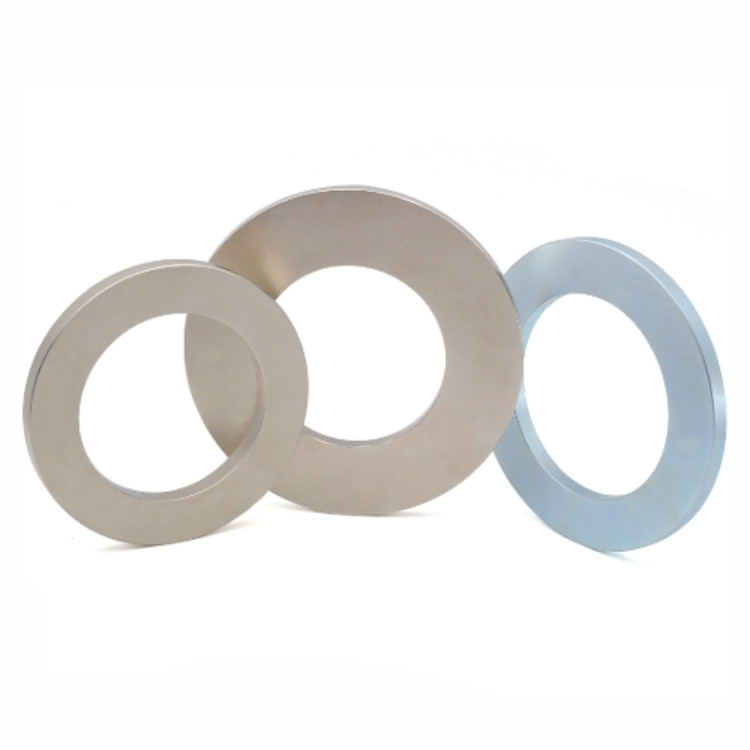

| 2.Custom Magnet Size Such as D10xD5x2mm , it is means the outer diameter is 10mm, inner diameter is 5mm, and thickness/height 2mm. |

3.Tolerance +/- 0.05 mm for the small dimension; +/- 0.1 mm for the common specification; |  |

| 4.Surface Coation Zn and Ni-Cu-Ni coating is the most popular coating.There have many plating options like Ni-Cu-Ni, Ni, Zn, Gold, Black Epoxy and so on. |

5.Magnetizing Direction With the Axial magnetizing, the magnetic spread over both flat side; with the Radial magnetizing, the magnetic spread over the surround. |  |

In order to quote you the best price quickly. please provide the following information:

Magnet grade, size,coating etc.

Order quantity.

Attached the drawing if customized.

Any special packing or other requirements.

Export Advantage:

All inquiries, questions and emails will be replied within 24 hours.

Samples and small quantity are available.

Stock material for stable production.

Most favorable Price is available.

Excellent shipping forwarder to help to delivery magnet.

Flexible Payment items include T/T in advance and western union and L/C at sight or others.

Quick delivery time & precise size tolerance.

Good quality and assured service.

FAQ:

Q1. Why are neodymium magnets coated?

A1. Neodymium magnets coatings are used to protect the neodymium magnets. Neodymium is easy to react to oxygen and oxidizes quickly if untreated. That's why all neodymium magnets are covered with a protective coating, which is so thin that it doesn't have any impact on the adhesive force of the magnet.

Q2. Is zinc plated magnetic?

A2. Even though zinc is a nonmagnetic metal, the coating is so thin that the magnetic properties of the steel are not hindered.

Q3. What is the protective coating for magnets?

A3. The typical coating for a Neodymium magnet is a layer of nickel followed by a layer of copper and then nickel again. However, there are many different coatings used on our magnets including gold, rubber, Polytetrafluoroethylene (PTFE) and more.

Q4. What is magnetic coating?

A4. This coating is the most commonly used on the surface of Neodymium or Rare Earth magnets. 3 layers in total, of nickel then copper and a final layer of nickel encase the Magnetic material to create a smooth, shiny finish and give conditional protection to the alloy compound inside.

Q5. How can you protect your magnet from getting demagnetize?

A5. Store your magnets with a keeper – A keeper is a small piece of iron that is generally added temporarily between the north and south poles of a magnet. It prevents the magnet from demagnetising by redirecting its magnetic field.