Strong Ndfeb Permanent Magnets Blocks

Customized strong Neodymium Block magnet

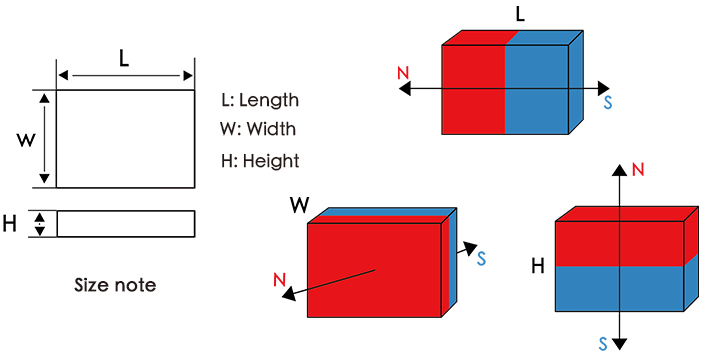

1.Shape and Dimension Requirement

2.Material and coating requirements

3. Processing according to design drawings

4.Requirements for Magnetization Direction

5. Magnet Grade Requirements

6. Surface treatment requirements (plating requirements)

Please contact us and we will be happy to provide pricing for any magnet you may need.

- Information

China factory customized strong N52 Neodymium Block magnet

Rare earth neodymium magnets are the strongest type of permanent magnet currently made. Neodymium magnets are composed of neodymium iron boron magnetic material and are plated in nickel-copper-nickel for a shiny corrosion resistant finish. Neodymium block magnets are magnetized through the thickness or Radial. Block magnet is the most popular shape of magnet . You can use small block magnet in toy, science experiments, woodworking, crafts, DIY and hobby projects. Large block magnet Generally used in industry for holding tool and linear motor.

Products description

Magnet Type: Sintered NeFeB / rare earth / Permanent

Composite: Neodymium-Iron-Boron

Shape: rectangle

Size: approx. 20 x 10 x 2mm/customized

Surface: Nickel plating

Tolerance: +/- 0.05mm

Shape of Magnet: Disc, Cylinder, Block, Ring, Sphere(ball), Arc Segment(Tile)

Grade: N35-N52( M, H, SH, UH, EH series )

Magnetization Direction Axially Magnetized, Radially Magnetized(Diametrically), Multi-poles Magnetized

Max working temperature for different grades

Grade | Max. Operating Temperatures |

N35-N52 | 80°C (176°F) |

33M- 48M | 100°C (212°F) |

33H-48H | 120°C (248°F) |

30SH-45SH | 150°C (302°F) |

30UH-40UH | 180°C (356°F) |

28EH-38EH | 200°C (392°F) |

28AH-35AH | 220°C (428°F) |

Surface Treatment

Neodymium magnets are usually coated to prevent the iron from rusting. Normally this is a Nickel-Copper-Nickel plating, however, Zinc, Tin, Black Nickel, Gold and Silver plating are also used as are Epoxy resin . The Gold and Silver plated magnets are often used to make homemade magnetic therapy jewellery. Particularly using a number of spheres to make necklaces or bracelets.

Magnetization side of block size

The magnetization side is according to your requirements.

For example: 10x5x3mm, the confirmation diameter is 10x5mm side.

Application

Neodymium block magnets are very varied but care must be taken because they are brittle and do not flex. They are normally only safe for use below 80oC/176oF although we do stock some high and extra high operating temperature magnets.

Smaller neodymium magnets are often used for jewellery clasps, magnetic therapy jewellery, magnetic earrings (one each side of the ear), fridge magnets, model train connectors, scalextric vehicles, re-born dolls, wargaming models, motors, science projects etc. Larger block magnets are used for science projects, actuators, separators, speakers, pumps, magnetic therapy and circuit breakers in power stations.

FAQ:

Q1. What are neodymium block magnets?

A1. Neodymium block magnets are strong magnets made of neodymium, iron, and boron. They have a rectangular or block-shaped design and are available in a variety of sizes and grades.

Q2. What are the benefits of using neodymium block magnets?

A2. Neodymium block magnets are known for their strength, durability, and versatility. They have a high magnetic pull, making them ideal for holding applications, and their rectangular shape makes them easy to use in a variety of settings.

Q3. What are the drawbacks of using neodymium block magnets?

A3. Neodymium block magnets can be brittle and can break if dropped or exposed to strong impact. They also have a very strong magnetic field and should be handled with care.

Q4. Do neodymium magnets attract gold?

A4. Neodymium magnets will also attract other rare earth magnets, such as samarium-cobalt magnets and cerium-iron-cobalt magnets. Neodymium magnets will not attract non-ferromagnetic materials, such as copper, aluminum, gold, and silver.

Q5. How do I choose a neodymium magnet?

A5. For Neodymium, Samarium Cobalt, and Ceramic materials, the grade is an indicator of magnet strength: the higher the material grade number, the stronger that magnet. Alnico is a notable exception to this rule. The size dependent nature of Alnico means grade will not always correlate with strength.