Sintered Ndfeb Arc Magnets supplier

We accept customized services:

1) Shape and Dimension Requirements

2) Material and coating requirements

3) Processing according to design drawings

4) Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

- Information

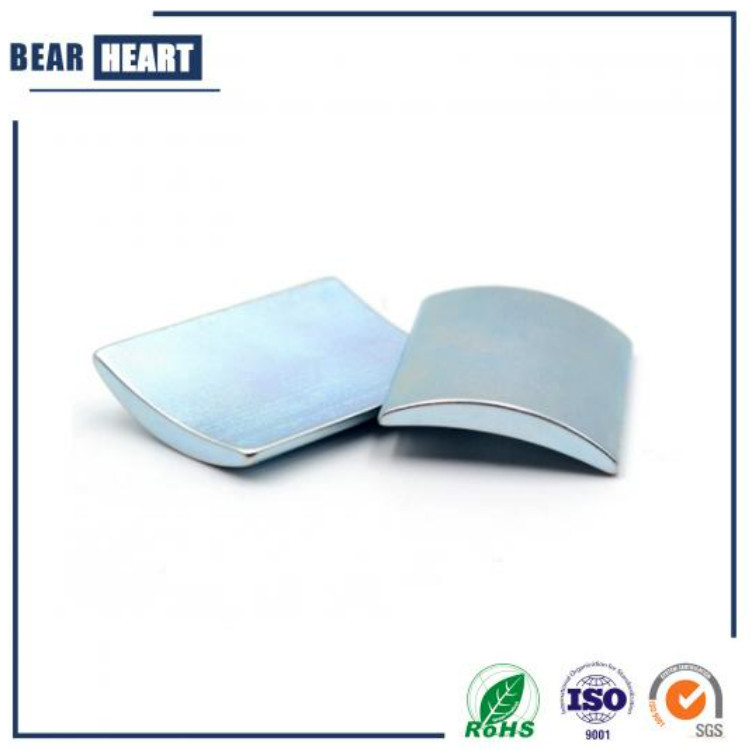

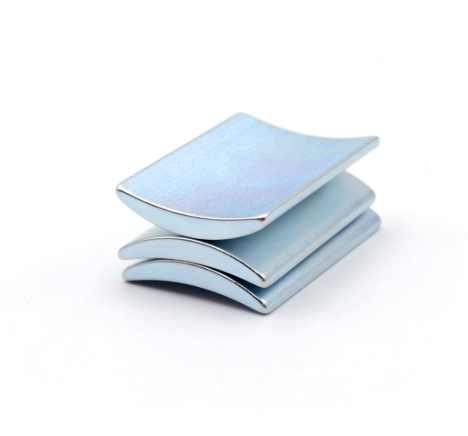

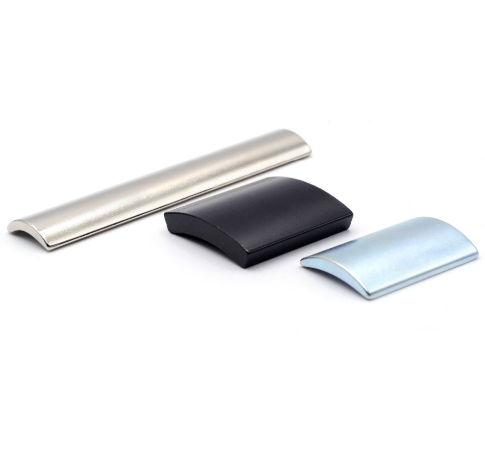

China Factory Custom Super Strong Neodymium Arc Tile Segment Ndfeb magnets

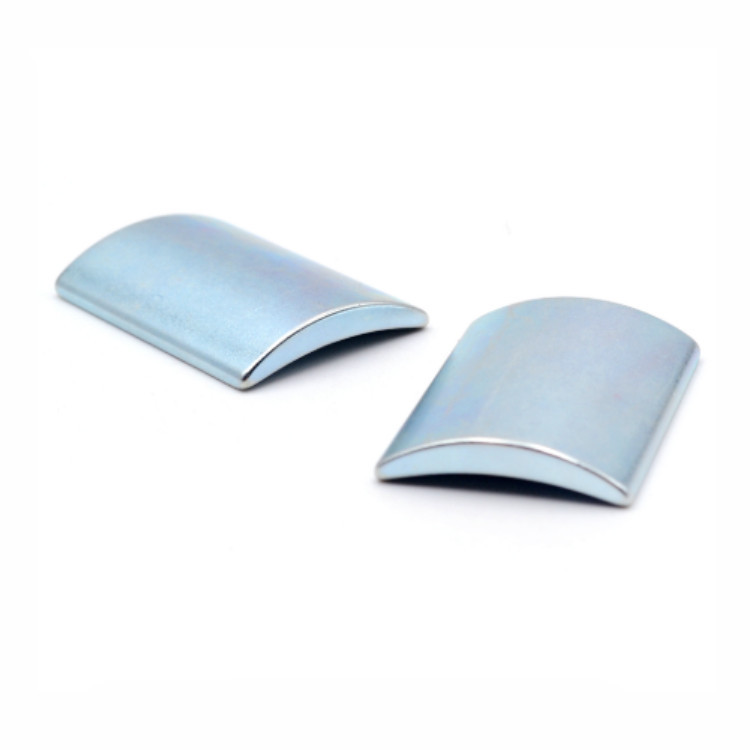

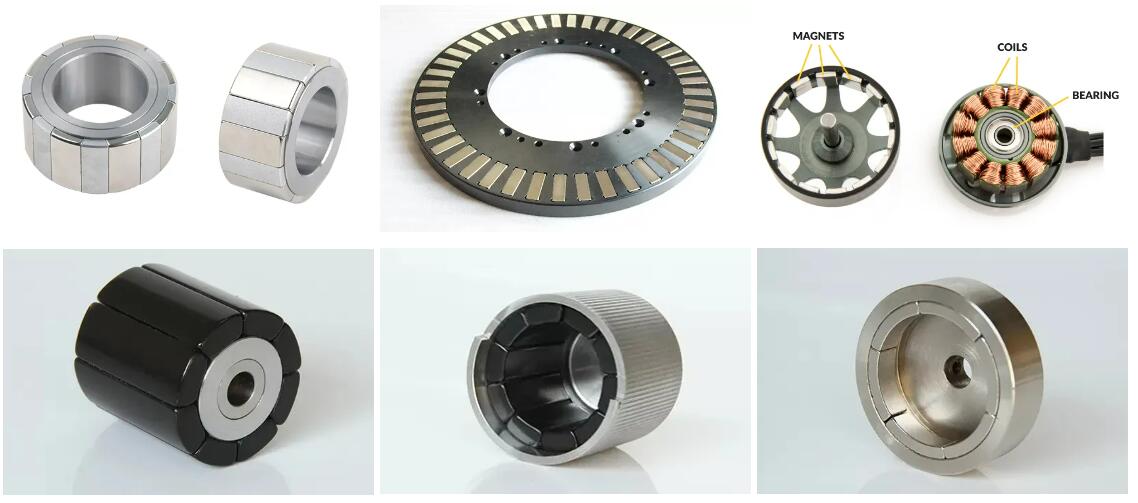

As the third generation of rare earth permanent magnet, Neodymium magnets are the most powerful commercially produced magnets. Neodymium arc magnet, also known as Neodymium curved magnet, is a unique shape of Neodymium magnet, then almost all of Neodymium arc magnet is used for both rotor and stator in permanent magnet (PM) motors, generators, or magnetic couplings.

Product Description

Product Name | Arc Shape Neodymium Magnets/Strong Segment NdFeB Magnet/Motor Segment Magnet | ||

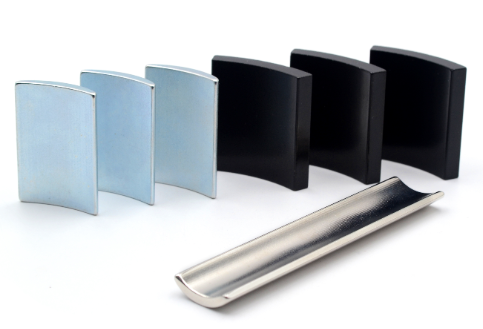

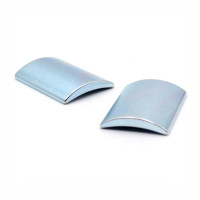

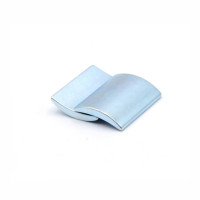

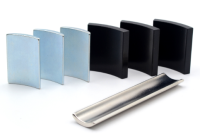

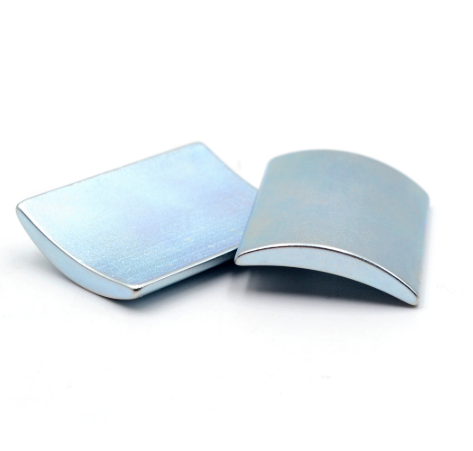

Grade | N35-N52 and so on | Coating | Epoxy,Zn and NI+CU+NI triple layer coating |

Shape | Arc,Segment,Tile,Curved, Bread, Wedge shaped and Arched magnets | Size | 2≤L≤158mm, 3≤W≤90mm, 1.5≤T≤50mm, more details, please contact us directly. |

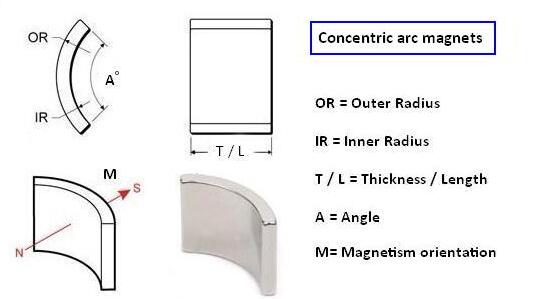

Magnetized direction | Axial/Diametral or as per following drawing | Tolerance | +/-0.1mm,+/-0.05mm or as per customer's drawing |

Package | Standard Export Package or customized size | ||

Product details

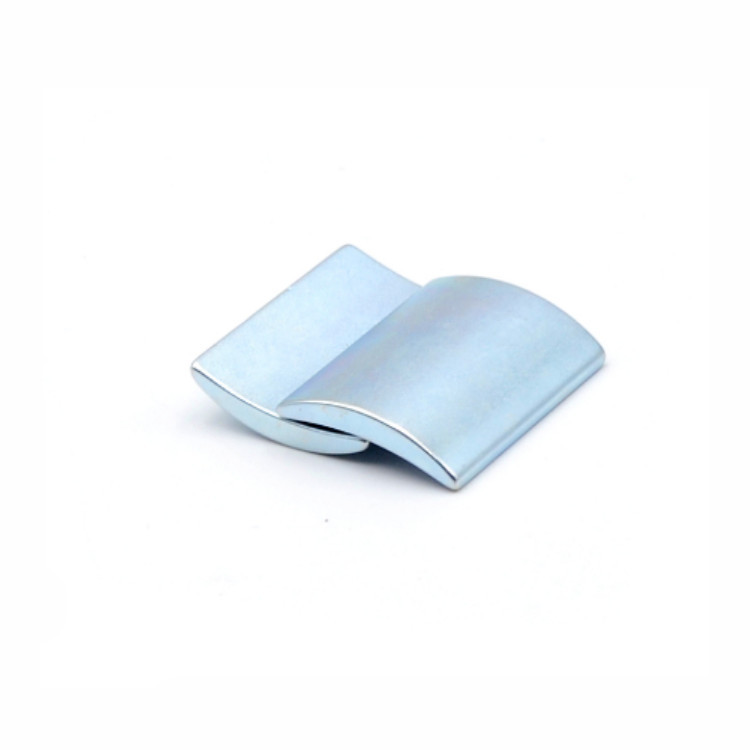

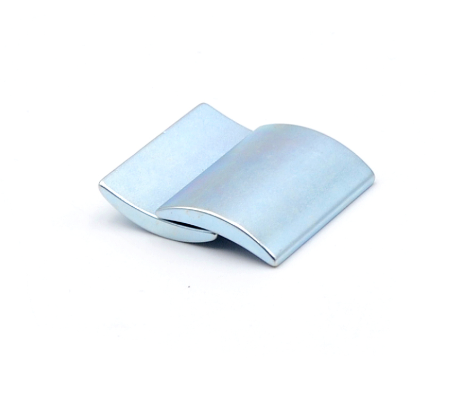

Machining Process of Arc NdFeB Magnet Due to technical limitations in the magnetic field orientation molding process, Neodymium arc magnet is always machined from blank. Machining process of curved magnet is normally selected from wire-cutting or copy grinding. Wire-cutting is well adapted to the machining of special shaped magnet, but it also accused of low production efficiency and high processing cost. On the contrary, copy grinding has the competitive advantage in efficiency and cost but short in dimensional applicability. Magnet manufacturers should utilize appropriate machining technology in accordance to the shape, dimension, material utilization ratio, production efficiency, and processing cost. |  |

| Magnetization Orientation Neodymium curved magnet for frequently-used radial flux motor is magnetized through diametrical direction and definitely used in pairs. It should be noted that pure radially magnetized arc magnet is extremely difficult to manufacture. Fan-shaped arc magnet is commonly served as axial flux motor magnet. For some axial flux motor, a certain quantity of chord magnetized magnet should be placed between regular axially magnetized magnet to form a Halbach array, then obtain more ideal magnetic field strength and distribution. |

Typical Coatings Plating neodymium magnets is an important process to protect the magnet against corrosion. The typical coating for a neodymium magnet is Ni-Cu-Ni coating.Some other options for coating are zinc, tin, copper, epoxy, silver, gold and more. |  |

Application

Strong Neodymium arc magnets are used in electronic, electrical machinery. medical equipment toys packaging. metal machinery, aerospace and othfields, the more common ermanent magnet motor, speaker, magnetic separator, computer disk drive, householdappliances, digital cameras, mobile phones, stationery, handicrafts, magnetic resonance imaging equipment etc.

FAQ:

Q1. What are neodymium arc magnets?

A1. Neodymium arc magnets are powerful magnets that have a curved shape or arc. They typically have a north and south pole on opposite ends of the arc.

Q2. What are the benefits of using neodymium arc magnets?

A2. Neodymium arc magnets are known for their strength, durability, and versatility. They have a strong magnetic pull and their curved shape makes them ideal for use in motors, generators, and other applications where a curved magnetic field is required.

Q3. What are the drawbacks of using neodymium arc magnets?

A3. Neodymium arc magnets can be brittle and can break if dropped or exposed to strong impact. They also have a very strong magnetic field and should be handled with care.

Q4. What is arc magnet used for?

A4. Top Quality Rare Earth Neodymium Arc Magnets are typically used in permanent magnet motors, generators and torque couplings. However, these may be found with sensors and holding applications.

Q5. Why are curved magnets stronger?

A5. This is because the shape affects the distribution of the magnetic energy in the space it occupies. The stereotypical u-shaped magnet that is portrayed in cartoons, is generally known as the most effective. This is due to the magnetic field concentrated between the poles, thus creating a stronger field.