Round NdFeB Neodymium Magnets

We provide High Quality rare earth neodymium magnets

Customize Shape: Disc, Ring, Block, Arc, countersunk magnets;

Customize Grade: N(N35-N52), M(N35-N50), H(N35-N48), SH(N33-N48), UH(N30-N40), EH(N28-N38), AH(N28-N35).

Customize Size: Diameter / Thickness Size From 1mm – 100mm.

- Information

Manufacturer wholesale neodymium disc magnet

Neodymium Magnets, also known as NdFeB, NIB, or Neo magnets, are the most widely-used type of rare earth magnets. Neodymium Magnets are made from an alloy containing, amongst others, the elements Neodymium, Iron and Boron (NdFeB). It is the strongest type of magnet and manufactured in a wide range of shapes, sizes and grades and different coatings/finishes.

Our Neodymium magnets are commonly used in creative applications such as models and theatre design, furniture making, exhibition stands and packaging. Neodymium disc magnets also have many uses in engineering and manufacturing where compact size and maximum strength are required. What's more, because of their resistance to demagnetisation they are ideal for creating a shock-absorbing or damping effect when used to repel other magnets.

Specifications of Sintered Neodymium Magnet

| Product Name | Neodymium Magnets |

| Material | Neodymium Iron Boron |

| Size | Custom made any size |

| Shape | Disc, Block, Cylinder, Ring, Rod, Arc Segment, Cube,Sphere etc |

| Grade | N35-N52,(M,H,SH,UH,EH,AH) |

| Working Temperature | 80ºC-220ºC |

| Coating | NiCuNi, Zinc , Epoxy etc |

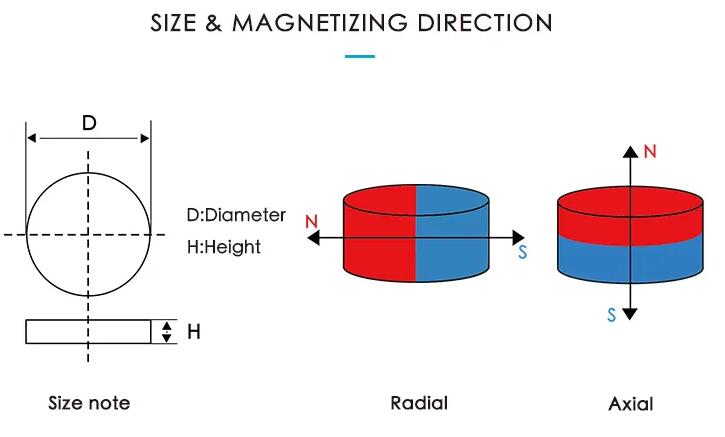

| Magnet Direction | Through thickness(Axially), Radially |

| Application | Sensors, motors, filter automobiles, magnetics holders, loudspeakers, wind generators, medical equipments, etc. |

Products Detail

1.MaterialThe raw materials are Nd, Fe and B. Starting from the selection of materials, high-quality neodymium-iron-boron magnets are produced with high-quality rare-earth materials and various mixed materials. |  |

| 2.Tolerance Use advanced slicing and line cutting equipment, professional and skilled operators, the conventional tolerance of the product is controlled at +/-0.05mm.(in case of special requirements, the tolerance can be accurately controlled at +/-0.03mm) |

3. CoatingIt has many conventional coatings, such as nickel, copper, nickel, zinc and black epoxy. The most common type of plating for neodymium magnet is Nickel (Ni-Cu-Ni) Intended for indoor use. After coating treatment, have good anti-rust, anti-corrosion ability. |  |

| |

Buyer Guide:In order to quote you the best price quickly, please provide the following information: | |

BEARHEART can supply large inventory of Neodymium magnets in disc, block, rod , ring , arc & customized irregular shapes, in a wide range of shapes, sizes and grades. Just let us know what you are looking for by sending us a request for quote or contact us to discuss your specialty project.

FAQ:

Q1. What is the major disadvantages of NdFeB?

A1. The advantages of the NdFeB magnets: NdFeB magnets have the best magnetic properties, good price, good strength, and are easy to process into special shapes. The disadvantages of the NdFeB magnets: NdFeB magnets are not resistant to high temperature and corrosion, and are fragile.

Q2. Is NdFeB a rare earth magnet?

A2. Neodymium magnets (also known as "NdFeB", "Neo" or "NIB" magnets) are permanent magnets made of neodymium, iron & boron. They are from the Rare-Earth magnet family and have the highest magnetic properties of all permanent magnets, stronger than Samarium Cobalt (SmCo), Alnico and Ferrite.

Q3. What is the highest grade neodymium magnet?

A3. As a very general rule, the higher the grade (the number following the 'N'), the stronger the magnet. The highest grade of neodymium magnet currently available is N52. Any letter following the grade refers to the temperature rating of the magnet.

Q4. Do neodymium magnets get weaker over time?

A4. Yes, magnets do weaken over time, but depending on the affection on it, it will retain it's magnetism essentially forever. If you store permanent magnets correct, neodymium magnets will likely lose less than 1% of their flux density over 100 years.

Q5. How do you demagnetize a NdFeB magnet?

A5. The induction heating method can demagnetize the large NdFeB magnets by heating the magnet to about 300 °C on the surface facing the induction heater, whereas a demagnetization using a gas torch might result in a much higher local surface temperature.