Permanent Y35 Block Ferrite Magnet

Ferrite magnets supplier:

1) Cheapest magnet material

2) Good anti-corrosion performance, no need to surface treatment.

3) Best temperature stability

4) Best choice for industrial application

5) All shapes can be customized

6) provide isotropic and anisotropic

- Information

Factory supply permanent Y35 Block Ferrite Ceramic Magnet

Ferrite block magnet (Ceramic magnet) is one of the most cost effective magnetic materials. Composed of Barium or Strontium Ferrite, these materials exhibit good resistance to demagnetization, and are the lowest cost materials available today. It has a fair to good resistance toward corrosion and it can operate in moderate heat. Ceramic (Ferrite) magnets have low energy product and they are usually used in assemblies containing mild steel. Sintered Ferrite magnets are hard and brittle and are extensively used in consumer products. You are probably familiar with ferrite magnets, often used on the back of refrigerator magnets.

Attributes of ferrite Magnet:

• Least expensive material compared to alnico and rare earth magnets

• High intrinsic coercive force

• Available in simple shapes only due to manufacturing process

• Lower service temperature than alnico, greater than rare earth

• Lower energy product than alnico and rare earth magnets

Ferrite Magnetic Parameter

Grade | BR | HcB | HcJ | (BH)max | ||||

mT | KG | KA/m | Koe | KA/m | Koe | Kj/m | MGOe | |

Y8T | 200~235 | 2.0~2.35 | 125~160 | 1.57~2.01 | 210~280 | 2.64~3.52 | 6.5~9.5 | 0.8~1.2 |

Y20 | 320~380 | 3.2~3.8 | 135~190 | 1.70~2.38 | 140~195 | 1.76~2.45 | 18.0~22.0 | 2.3~2.8 |

Y22H | 310~360 | 3.1~3.6 | 220~250 | 2.77~3.14 | 280~320 | 3.52~4.02 | 20.0~24.0 | 2.5~3.0 |

Y23 | 320~370 | 3.2~3.7 | 170~190 | 2.14~2.38 | 190~230 | 2.39~2.89 | 20.0~25.5 | 2.5~3.2 |

Y25 | 360~400 | 3.6~4.0 | 135~170 | 1.70~2.14 | 140~200 | 1.76~2.51 | 22.5~28.0 | 2.8~3.5 |

Y26H | 360~390 | 3.6~3.9 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 23.0~28.0 | 2.9~3.5 |

Y27H | 370~400 | 3.7~4.0 | 205~250 | 2.58~3.14 | 210~255 | 2.64~3.21 | 25.0~29.0 | 3.1~3.7 |

Y28 | 370~400 | 3.7~4.0 | 175~2102 | 2.20~2.64 | 180~220 | 2.26~2.77 | 26.0~30.0 | 3.3~3.8 |

Y30H-1 | 380~400 | 3.8~4.0 | 230~275 | 2.89~3.46 | 235~290 | 2.95~3.65 | 27.0~32.0 | 3.4~4.1 |

Y30H-2 | 395~415 | 3.95~4.15 | 275~300 | 3.46~3.77 | 310~335 | 3.90~4.21 | 28.5~32.5 | 3.5~4.0 |

Y32 | 400~420 | 4.0~4.2 | 160~190 | 2.01~2.38 | 165~195 | 2.07~2.45 | 30.0~33.5 | 3.8~4.2 |

Y33 | 410~430 | 4.1~4.3 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 31.5~35.0 | 4.0~4.4 |

Y35 | 430~450 | 4.3~4.5 | 215~239 | 2.70~3.00 | 217~241 | 2.73~3.03 | 33.1~33.2 | 4.16~4.17 |

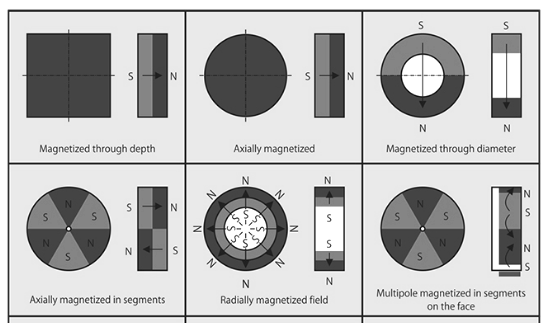

Magnetization

1.Isotropic ferrite magnets are not oriented and can be magnetized in any direction;

2.Anisotropic ferrite magnets are different, they are all oriented in the manufacturing direction, and should be magnetized in the direction of orientation.

Two manufacturing Process

1. Dry process: By dry process, can produce isotropic & anisotropic magnets;the tool can be changed and developed easily.

2. Wet process: By wet process, only anisotropic magnets can be produced;it is complicated to change the tool and the tooling charge is much higher.

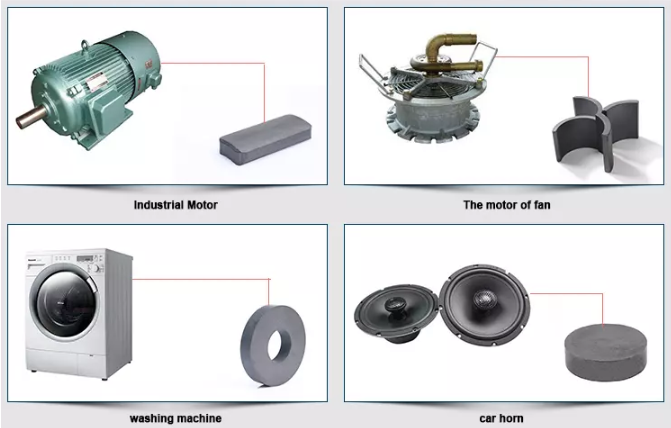

Ferrite Magnet Applcation:

The permanent ferrites magnets have character of various specifications, cheapness, etc. They are widely used in very sorts of motors, electro-acoustic, magnetic force machines, duplicators, magnetron fields, household apparatus, magnetic couplings, for sensing, loudspeakers, holding-magnet system, crafts, magnetic therapy, novelties and toys.

FAQ:

Q1. What are the applications of Y35 ferrite block magnets?

A1. Ferrite block magnets are often used in automotive and medical applications, as well as in various industrial devices, magnetic separators, and speakers.

Q2. How are Y35 ferrite block magnets made?

A2. Y35 ferrite agnets are made by pressing ferrite powder and a binder into a mold, followed by sintering the magnet in a furnace at high temperatures. They are then cut into a rectangular or square shape and magnetized.

Q3. What are the advantages of Y35 ceramic block magnets?

A3. Y35 ceramic block magnets have a high resistance to demagnetization, good temperature stability, and are relatively low-cost compared to other types of magnets.

Q4. What are the disadvantages of Y35 ferrite block magnets?

A4. Y35 ferrite ceramic block magnets have lower magnetic strength compared to other types of magnets, and their magnetic properties are uniform in all directions, limiting their versatility.

Q5. Can Y35 ferrite block magnets be customized?

A5. Yes, ferrite magnets can be customized in terms of their size, shape, and magnetic strength to suit specific applications.