Permanent Ferrite Round Ring Magnets

Ferrite magnets Features:

1) Cheapest magnet material

2) Good anti-corrosion performance, no need to surface treatment.

3) Best temperature stability

4) Best choice for industrial application

5) All shapes can be customized

6) provide isotropic and anisotropic

- Information

Professional magnets China Manufacturer Y35 Permanent Ring Ferrite Magnet

Also known as ceramic magnets, ferrite magnets offer excellent value for money when pull strength is not the most important factor. They have a high resistance to corrosion and demagnetization and can operate in temperatures up to 180oC. Ferrite ring magnets are made specifically for loudspeaker systems and their sizes have evolved with demand from this market. However, they are also commonly used in magnetic rollers for separating applications and in the printing industry. They are also a vital component found in fast running conveyor systems in many manufacturing plants dealing with ferrous material.

Attributes of Ceramic Magnets:

• Least expensive material compared to alnico and rare earth magnets

• High intrinsic coercive force

• Available in simple shapes only due to manufacturing process

• Lower service temperature than alnico, greater than rare earth

• Lower energy product than alnico and rare earth magnets

• Most common grades of Y25,Y30,Y30H-1,Y30H-2,Y32,Y33 ceramic are 1, 5 and 8 (1-8 possible)

Key Challenges Of Ceramic Magnet Material

Hard and brittle.

Properties degrade linearly with temperature. At 350°F (177°C), about 75% of room temperature magnetization is retained, and at 550°F (288°C), about 50% is retained.

Ferrite magnets characteristics

Material |

|

|

|

|

| ||||

Br(mT) | Br(Gs) | bHc(KA/m) | bHc(Oe) | iHc(KA/m) | iHc(Oe) | (BH)max(KJ/m 3 ) | (BH)max(MGOe) | ||

Y10T | Isotropic | ≥200 | ≥2000 | ≥125 | ≥1600 | ≥210 | ≥2600 | ≥6.5 | ≥0.8 |

Y20 | Anisotropic | ≥360 | ≥3600 | ≥135 | ≥1700 | ≥140 | ≥1760 | ≥20.0 | ≥2.5 |

Y25 | Anisotropic | ≥380 | ≥3800 | ≥144 | ≥1800 | ≥150 | ≥1880 | ≥24.0 | ≥3.0 |

Y30 | Anisotropic | ≥390 | ≥3900 | ≥184 | ≥2300 | ≥188 | ≥2350 | ≥27.6 | ≥3.4 |

Y30BH | Anisotropic | ≥390 | ≥3900 | ≥240 | ≥3000 | ≥256 | ≥3200 | ≥27.6 | ≥3.4 |

Y35 | Anisotropic | ≥410 | ≥4100 | ≥208 | ≥2600 | ≥212 | ≥2660 | ≥30.4 | ≥3.8 |

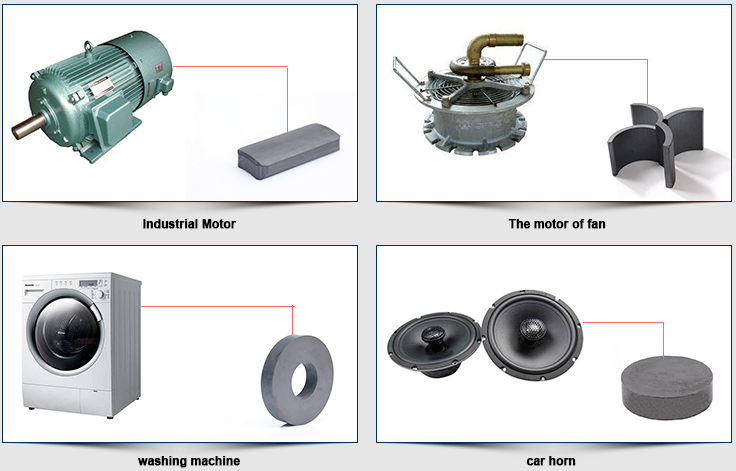

Application

Ferrite Ring magnets can be used in a wide range of applications due to their high coercivity and low cost. Common applications include reed switches, loud speakers, security systems, audio and television and also holding devices such as pot magnets. Our ferrite ring magnets are often used in loudspeakers and also in resonance imaging and torque drives.

FAQ:

Q1. What is a ferrite ring magnet?

A1. A ferrite ring magnet is a type of permanent magnet made from ceramic materials that provide high magnetic strength and resistance to demagnetization.

Q2. What is the typical shape of a ferrite ring magnet?

A2. A ferrite ring magnet is typically in the shape of a donut or a ring, with a hole in the center.

Q3. What are the applications of ferrite ring magnets?

A3. Ferrite ring magnets are commonly used in various electronic devices such as speakers, motors, generators, and sensors.

Q4. How strong are ferrite ring magnets?

A4. Ferrite ring magnets have a moderate magnetic strength compared to other types of magnets, but they are more resistant to demagnetization.

Q5. Can ferrite ring magnets be customized to fit specific requirements?

A5. Yes, ferrite ring magnets can be produced in various sizes and shapes to fit specific requirements depending on the application.