D22 Neodymium mounting magnets with rubber coating

Features of Rubber Coated Pot Magnet:

1. Waterproof

2. Strong Force

3. Durable

4. Easy to Use

- Information

Rubber coated circular Disc magnets supplier Cheap price

Rare Earth holding pot magnets (Neodymium) are high strength rare earth magnets in a mild steel cap for extra protection against chipping or cracking. Rubber coated pot magnets are often placed to create a fixing or hanging point. The rubber coating provides for superior slide resistance due to greater friction between the rubber and steel surface to which the magnet is bonded. Manufacturers and industrial designers use rubber coated pot magnets for holding and fastening.

Product Description

Product Name | Rubber Coated POT Magnet |

Material | Neodymium + A3 steel + TPE Rubber |

Color | Black |

| Type | Internal thread, external thread, flat thread, etc. |

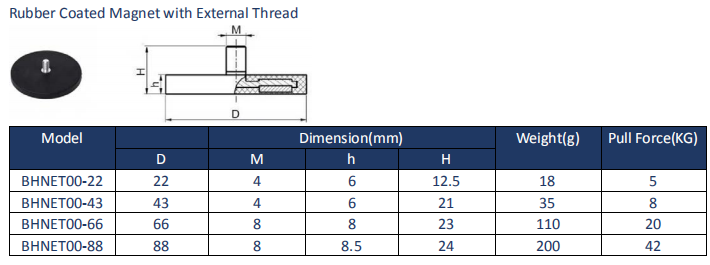

Standard | Diameter 22mm/30mm/43mm/66mm/88mm or customized |

Pull force | As customers' request |

Thread | M5/M6/M8/M10 |

Used | Holding Magnet, Portable, easy to carry. Can be used on car, offroad, trucks, jeep, boat, etc.Can mount any off-road lights, LED work lights, LED light bar, etc. |

Features

* Produced by the powder metallurgical method

* Chemical composition of Nd2Fe14B

* Very brittle and hard

* Poorest corrosion resistance of all commercial magnetic material

* Excellent cost to performance ratio

* Reasonable temperature stability

* Not suitable for application which exposed to high temperatures

* High resistance to magnetic demagnetization.

Custom made avaiable

Our Neodymium pot magnets are offered in a variety of dimensions, sizes and shapes, with countersunk holes or round holes, male or female thread or with a threaded hook. Due to their versatility, BEARHEART Magnetics rare earth pots can be used in many commercial and industrial applications such as keeping doors open or closed, cabinetry, holding, fixing, attaching objects to walls, ceilings, structures, vehicles or any ferrous metallic object or surface.

Application

This rubber pot magnets are often used for holding, gripping or clamping functions. Rubber coated mounting magnets sometimes feature a central threaded hole so that you can attach them with a bolt. Alternatively you can insert a hook or eyebolt.

Rubber coating of pot magnets is considered useful when using sensitive surfaces like glass and plastics, or highly finished vehicular surfaces. Rubber coating is also useful to prevent corrosion in marine, aquatic or external environments, as well as in areas where metal strike presents a risk to the magnet. Metal strike situations are more likely in mechanical environments related to motors and machinery.

FAQ:

Q: What are rubber coated neodymium pot magnets?

A: Rubber coated neodymium pot magnets are powerful magnetic assemblies that feature a neodymium magnet core wrapped in a protective layer of rubber. The rubber coating offers protection against scratches, chips, and corrosion, making these magnets ideal for use in harsh environments.

Q: What are the main benefits of rubber coated neodymium pot magnets?

A: Rubber coated neodymium pot magnets offer numerous benefits. They are strong and durable, they can be used in wet or dirty environments, and they won't damage surfaces or leave marks.

Q: What are some common applications for rubber coated neodymium pot magnets?

A: Rubber coated neodymium pot magnets are versatile and can be used in many different applications. Some common uses include holding, locating, and securing metal parts, holding signs and posters to metal surfaces, and retrieving metal objects from hard-to-reach places.

Q: How do I select the right size and strength of rubber coated neodymium pot magnet for my application?

A: The size and strength of the magnet you need will depend on your specific application. You should consider factors such as the weight and size of the object you need to hold or secure, as well as the strength of the magnet needed to do so. You can consult a magnet supplier or engineer to help you select the right magnet.

Q: How do I properly install and maintain rubber coated neodymium pot magnets?

A: To install rubber coated neodymium pot magnets, simply place them against a metal surface. To remove, use a pry bar or other tool to carefully separate the magnet from the surface. Maintenance is minimal, but you should periodically inspect the rubber coating for cracks, chips, or other damage, and replace the magnet if necessary.