Black Epoxy Disc NdFeB Magnet supplier

Supper strong China Manufacturer Black epoxy Coated Disc Neodymium Magnets

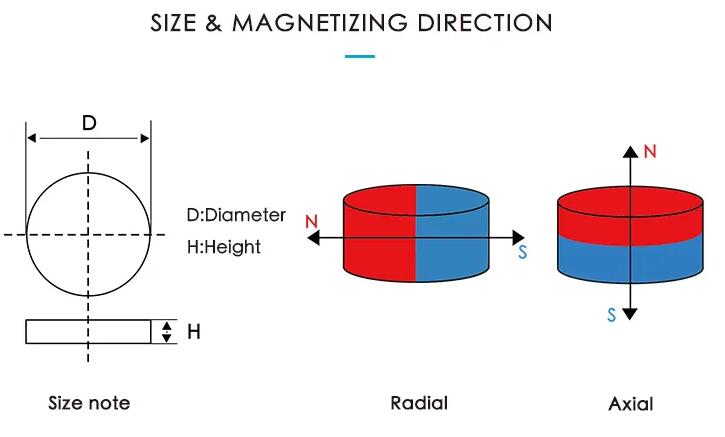

Customize Shape: Disc, Ring, Block, Arc, countersunk magnets;

Customize Grade: N(N35-N52), M(N35-N50), H(N35-N48), SH(N33-N48), UH(N30-N40), EH(N28-N38), AH(N28-N35).

Customize Size: Diameter / Thickness Size From 1mm – 100mm.

- Information

Customized black epoxy coated NdFeB permanent rare earth disc neodymium magnet

Neodymium Permanent Magnet (also well known as NdFeB, NIB or Neo magnet ), the most widely used type of rare-earth magnet, is a permanent magnet made from an alloy of neodymium, iron and boron to form the Nd2Fe14B tetragonal crystalline structure.Multiple choices of shapes can meet specific customer requirements. Black Epoxy coating is excellent as a barrier for salt air and salt water. However, it can be scratched easily, it must be handled carefully during assembly. Black epoxy has a very good adhesion to steel with magnet rated glue. We specialize in providing strong high-quality neodymium-iron-boron (NdFeB) magnets. Our neodymium magnets are made with the world's most advanced magnetic materials.

Features

Neodymium disc magnets with Epoxy coating overcome the corrosion problems associated with traditional Nickel-based coatings. This makes them ideal for outdoor use and locations where exposure to corrosive elements occurs, including Marine, Industrial and Agricultural environments. Epoxy also increases mechanical strength to the normally brittle Neodymium material and makes the magnet more durable.

However, the added cost and the air gap created by the coating make Epoxy coated magnets slightly less powerful and more expensive. Higher magnetic grades like this N52 item are used to help overcome this reduction in power. For specialized, long term use in exposed environments, Epoxy coated Neodymium magnets can provide long-lasting performance and increased durability in situations where uncoated magnets would degrade and eventually fail.

Products Detail

1.MaterialThe raw materials are Nd, Fe and B. Starting from the selection of materials, high-quality neodymium-iron-boron magnets are produced with high-quality rare-earth materials and various mixed materials. |  |

| 2.Tolerance Use advanced slicing and line cutting equipment, professional and skilled operators, the conventional tolerance of the product is controlled at +/-0.05mm.(in case of special requirements, the tolerance can be accurately controlled at +/-0.03mm) |

3. CoatingIt has many conventional coatings, such as nickel, copper, nickel, zinc and black epoxy. The most common type of plating for neodymium magnet is Nickel (Ni-Cu-Ni) Intended for indoor use. After coating treatment, have good anti-rust, anti-corrosion ability. |  |

| |

Buyer Guide:In order to quote you the best price quickly, please provide the following information: | |

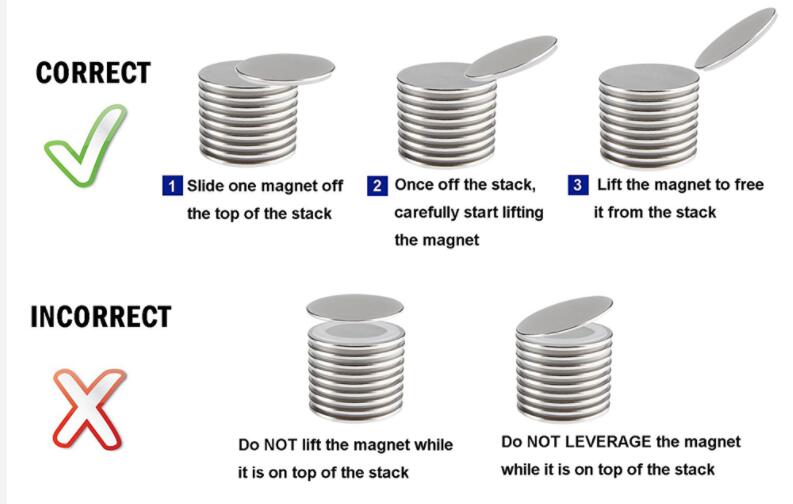

Caution

Neodymium magnets ( Nd2Fe14B Magent ) can be dangerous, as they generate extremely strong pull forces, therefore must be handled with care to avoid personal injury and damage to the magnets. Fingers and other body parts can get severely pinched between two attracting magnets. Neodymium disc magnets are brittle, and can shatter if allowed to slam together, launching small pieces at great speeds. Eye protection should be worn when handling there magnets.

FAQ:

Q1. What are neodymium magnets coated with?

A1. The typical coating for a neodymium magnet is a layer of nickel followed by a layer of copper and then nickel again. However there are many different coatings used with neodymium magnets including gold, rubber and Polytetrafluoroethylene (PTFE).

Q2. Which is better ferrite or neodymium?

A2. A rare earth or neodymium magnet is the most powerful of any permanent magnets and is around 2-7 times stronger than a regular or ferrite magnet. It can lift more than any other type of magnet of the same size.

Q3. Are there waterproof magnets?

A3. Magnets with waterproof plastic coating: High adhesive force thanks to neodymium. All waterproof neodymium magnets in this category are completely encased in plastic. Due to the robust coating, they have several advantages.

Q4. Are neodymium magnets rust proof?

A4. Neodymium magnets are like iron: without protection, they rust easily. To prevent corrosion, most neodymium magnets are plated with a three layer, nickel-copper-nickel plating. This particular plating combination has been the preferred corrosion protection for many years.

Q5. Do magnets rust in water?

A5. Magnets need iron to attract, and iron rusts when exposed to oxygen and water. Rust reduces the attraction of a magnet, and often makes it unsuitable for your purpose after a short period of time.