- Home

- >

News

Magnetic materials are magnetically ordered materials that have ferromagnetic or ferrimagnetic properties and have practical application value. A fundamental difference between them and other materials is that they are sensitive to external magnetic fields. Broadly defined magnetic materials also include antiferromagnetic materials and other weakly magnetic materials that have practical or possible application value.

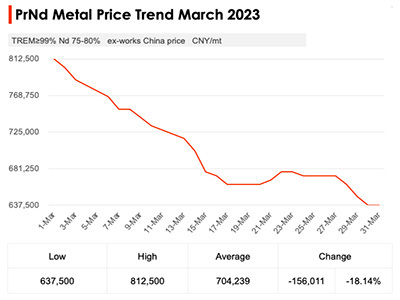

In the first half of 2023, the price trend of the domestic light rare earth market fell sharply. The price of neodymium oxide market at the beginning of the year was 770,000 yuan/ton, and the market price in the middle of the year was 477,500 yuan/ton, with a half-year price drop of 37.99%...

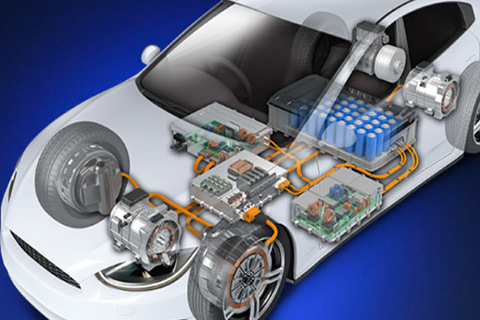

Neodymium iron boron (NdFeB) permanent magnets are widely used in the motor industry due to their advantages of high coercivity, high residual magnetism, and high magnetic energy product. In this article, we will mainly introduce the knowledge related to permanent magnet motors, hoping to be helpful for you.

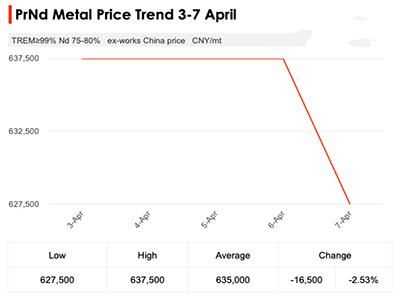

Last week, the price of light rare earth parts in China has declined and the sales on the floor and downstream purchase are not so bad. It is expected that the price trend will decline in the later stage.

According to the business community monitoring shows that the rare earth market price index fell sharply in March, the domestic rare earth market trend continues to decline.

Rare earth is widely used and continues to expand. Rare earth plays an important role in improving product performance, upgrading product structure and transforming to clean energy. It is not only involved in traditional fields such as agricultural light textile, metallurgical industry, petrochemical industry, glass and ceramics, but also key materials in emerging industries such as production of special light sources and related equipment, national defense and military, and intelligent manufacturing.

The production process of rare earth permanent magnet materials is a constantly evolving process. In the early production process, metallurgy was the main method. Rare earth elements were extracted by high-temperature smelting, and then magnetic materials with strong magnetic properties were prepared by chemical reduction and vacuum smelting. The process of this method is complicated, the production cost is high, and there is a risk of environmental pollution.