When the new energy meets the robot high-performance NdFeb magnetic material demand structure will meet great changes

2023-03-20 11:35Rare earth is widely used and continues to expand. Rare earth plays an important role in improving product performance, upgrading product structure and transforming to clean energy. It is not only involved in traditional fields such as agricultural light textile, metallurgical industry, petrochemical industry, glass and ceramics, but also key materials in emerging industries such as production of special light sources and related equipment, national defense and military, and intelligent manufacturing. Permanent magnet materials are the main application field of rare earth, accounting for 26% of global rare earth demand structure in 2020, and 42% of China's rare earth demand structure. The rapid development of rare earth permanent magnet materials has penetrated into many fields, such as robots, wind power equipment, new energy vehicles, energy-saving electrical appliances, precision instruments, etc., providing a huge driving force for the development of the rare earth industry. Common permanent magnet materials are usually divided into three categories, namely metal permanent magnet, ferrite permanent magnet and rare earth permanent magnet. And NdFeb, as the third generation rare earth permanent magnet material, has the advantages of high remanence magnetic density, high coercivity and high magnetic energy product. It is the strongest magnetic permanent magnet material so far, the most widely applied, the fastest developing speed and the best comprehensive performance of rare earth permanent magnet material.

China is the largest producer of NdFeb permanent magnet materials

Global output of rare earth permanent magnet materials is increasing steadily. Overall, from 2015 to 2020, the global output of rare earth permanent magnet increased from 150,000tons to 217,000 tons, among which China, as the main producer, increased from 135,000 tons to 196,000 tons. It is expected that the future production capacity of rare earth permanent magnet materials will continue to maintain optimistic growth, assuming that the global production compound average annual growth rate of 7.4%, by 2025, the global production of 310,000 tons, of which China produces 284,000 tons. In recent years, with the technological progress of Chinese production enterprises and the policy encouragement of transformation to high-end products, the output of high-performance ndfeb magnetic material in China floats rapidly, accounting for nearly 70% of the world output.

The raw material cost of NdFeb magnetic material is affected by the price of upstream rare earth

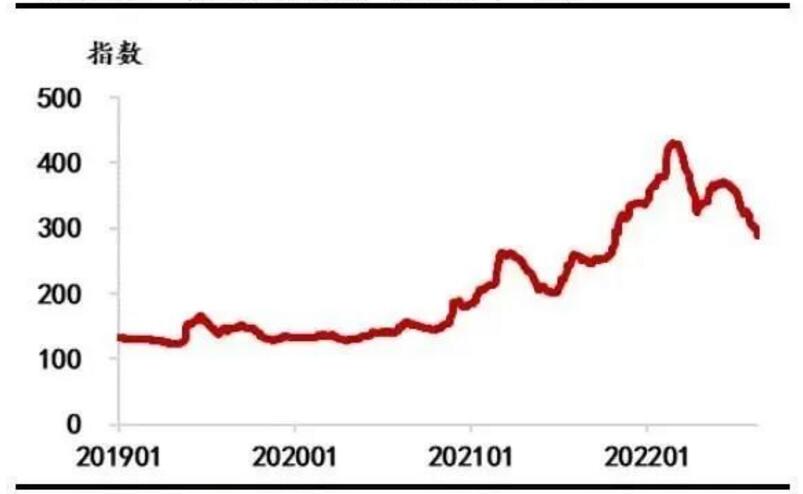

The continuous sharp rise that began in June 2021 came to a halt in March this year, as prices of rare earth products fell from high levels, making it cheaper for magnetic material companies to buy raw materials. First, the Russia-Ukraine conflict and the new wave of Omicron have led to a surge in energy and raw material prices, supply chain disruptions, and a severe impact on production capacity and demand in downstream applications. In the future, the total index of rare earth mining and smelting may continue to maintain the current level or increase slightly. However, the difficulty of rare earth mining continues to rise, the room for increasing rare earth production is limited, and there is little room for suppliers to further yield profits. The tight supply pattern of rare earth market will continue. The price fluctuation of raw materials in the upstream of the rare earth industry chain is transmitted to the downstream application products. Supply and demand are the most important factors affecting the price. The recent decline of rare earth prices has reduced the cost of raw materials for magnetic material enterprises.

Demand for high-performance NdFeb magnets for new energy vehicles

New energy vehicles are expected to become the core driving force to improve the demand for high-performance Ndfeb magnetic materials. It is expected that by 2025, the global sales volume of new energy vehicles will reach 23.274 million, of which 13.732 million will be sold in China, accounting for 59%. Based on the average consumption of 2.5kg of high-performance NdFeb magnetic material for each new energy vehicle, the global demand for high-performance NdFeb in 2025 can reach 58,000 tons, and China's demand is expected to reach 34,000 tons.

Demand for high-performance NdFeb magnets in traditional vehicles

The application of high-performance Ndfeb magnets in traditional vehicles is mainly electric power steering system (EPS), which plays a key role in vehicle stability, comfort and safety. China's auto production is expected to continue growing at a compound annual growth rate of 4% from 2022 to 2025. According to the EPS system needs 0.25kg high-performance NdFeb magnetic material calculation, by 2025, the global traditional automotive field demand for high-performance NdFeb will exceed 21,000 tons.

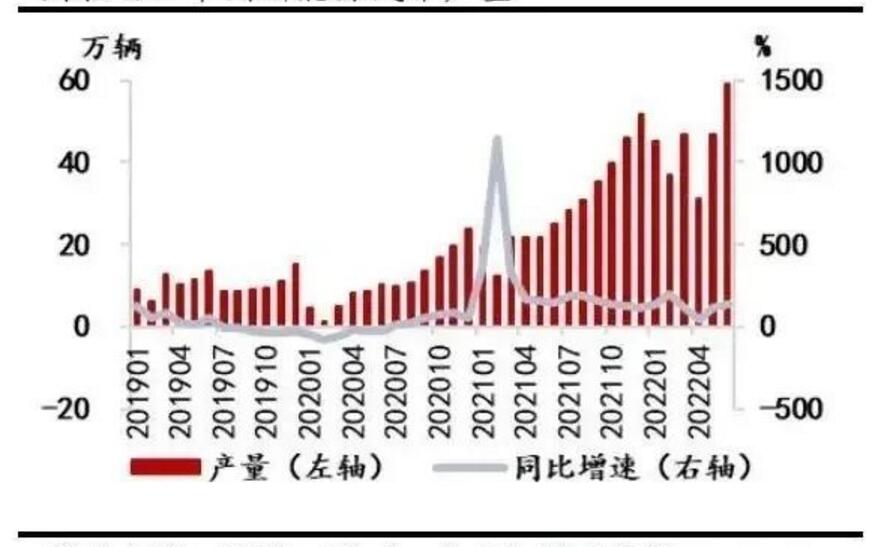

Demand for high performance NdFeb magnets for industrial robots

The development status of the robot industry is an important indicator to measure a country's level of scientific and technological innovation and high-end manufacturing. Accelerating the high-quality development of the robot industry is beneficial to inject strong momentum into economic and social development. Industrial robot is the realization of intelligent manufacturing automation equipment, currently mainly refers to the industrial field of multi-joint manipulator or multi-degree of freedom robot, used in the process of industrial production handling, welding, assembly, processing, painting, clean production, etc. The driving motor is the core part of industrial robot, and the permanent magnet synchronous servo motor is the mainstream. High performance rare earth permanent magnet material is the key material of servo motor, which helps to simplify the structure, reduce the volume, save energy and improve the power and stability of the motor. The rapid growth of Chinese robot industry scale, industrial robots become more and more popular. By 2020, the revenue of robot industry has exceeded 100 billion yuan. Since 2012, although the industrial robot industry has developed slowly in Europe and the United States, it has been booming in the Asian market. In 2021, the output of industrial robots in China reached 366,000 units, up 54.4 percent year on year. From January to June of 2022, the production volume exceeded 202,000 units, an increase of 16.6% compared to the same period last year.

Intelligent robots may become another pole of growth in demand for NdFeb

Intelligent robots mainly include industrial robots, professional service robots and personal/home robots. High-performance Ndfeb magnets are mainly used in sensors and drive motors of intelligent robots, and are the core materials of servo motors, the core parts of robots. Musk is very optimistic about the development of the robot industry in the future. He believes that with the progress of technology and the expansion of production scale, the average cost will gradually decrease, and the price of household robots may be lower than that of automobiles, becoming a normal consumer product within the range of consumers' general affordability. He also predicts that every home will have a robot by 2050. The robot industry is booming and the global robot market will reach $51.3 billion in 2022, with an average annual growth rate of 14 percent from 2017 to 2022, according to the China Robotics Industry Development Report (2022) released by the Chinese Society of Electronics. In terms of categories, the market scale of service robots is growing gradually. By 2021, the market scale of service robots is almost equal to that of industrial robots and maintains a good growth trend. It is expected to become the leading force in the global robot market in the future.

In China, industrial robots account for the largest market size, much higher than service robots and special robots. In 2021, China's robot market reached 14.2 billion US dollars, of which industrial robots accounted for 52.8 percent, 7.5 billion US dollars. Service robots, $4.9 billion, 34.5%; Special robots, $1.8 billion, accounted for 12.7 percent. However, in terms of scale growth, the service robot market is growing faster, and service robots will become an important supporting force for the continuous growth of the robot market. Robots will help fill gaps in the workforce and reduce social spending in some ageing countries. Musk's entry could be the key to exploding the current robotics market, disrupting the robotics industry and even the socioeconomic demand structure by accelerating the upgrading and iteration of existing robotics technologies. That's why Tesla's humanoid robots are getting so much attention. Take Tesla humanoid robot as an example, there are 40 motors in the whole body, and each motor consumes 50g-100g high-performance Ndfeb magnetic material. Therefore, each humanoid robot needs to consume 2-4kg high-performance NdFeb magnetic material. By 2030, the global humanoid robot field demand for high-performance ndfeb magnetic material will exceed 90,000 tons, which will greatly change the downstream demand structure of high-performance NdFeb magnetic material.

New energy vehicles and humanoid robots will change the balance of NdFeb supply and demand

The downstream demand of high-performance Ndfeb magnetic material is mainly concentrated in the fields of new energy vehicles, traditional vehicles, wind power generation, energy-saving frequency conversion air conditioning, energy-saving elevators, consumer electronics, industrial robots, the sum of the demand of the above fields accounts for about 95%. Currently, wind power is the leading sector, with less demand for traditional automobiles and consumer electronics, and little difference in the share of demand for other major applications. As the new energy automobile industry continues to maintain rapid development in the future, the demand for new energy vehicles will be greatly boosted from 2020 to 2025, becoming the main consumption area of ndFeb magnetic materials in the world, accounting for 29.1% in 2025. Tesla announced that it will officially start production of humanoid robots in 2023. Although humanoid robots still face the difficult problem of technology upgrading and cost reduction before 2025, it is difficult to put into mass production and has a weak impact on the global demand structure of high-performance ndfeb magnetic materials. However, in 2030, it is expected that humanoid robots have entered a period of rapid development and large-scale production will emerge, becoming the biggest driving force driving the global demand for high-performance ndfeb magnetic materials and greatly changing its demand structure.