How to avoid demagnetising a magnet?

Demagnetisation is the process whereby a magnet loses all of its magnetic properties. The magnet most prone to demagnetisation is the ferrite magnet due to the alloy it is made of, however all magnets can be demagnetised. To avoid demagnetising your magnet, follow these guidelines:

Separating your magnets

Make sure you separate any magnets that have become attached to one another by directly pulling them apart. Any other movement to separate the two may damage the magnets and potentially demagnetise them.

Keep away from high temperatures

High temperatures are the only way to demagnetise a magnet to a point where it cannot be re-magnetised. All other forms of demagnetisation can be put right by re-magnetising the magnet. For example, using a magnet, without a steel casing to protect it, to retrieve ferromagnetic objects from a plating vat would damage the magnet.

Magnetic domains within an object need to be aligned in the same direction in order for an object to be magnetic. High temperatures cause the magnetic domains to move and become disorganised. This means that they are no longer aligned in the same direction, therefore the magnet will no longer be magnetic.

The maximum operating temperature of a magnet will tell you the maximum temperature the magnet can be continuously subjected to with no significant loss of its magnetic strength. This information can usually be found in the product spec and should be available for every variety of magnet.

Alnico magnets are the best suited magnets for use in high temperatures as they have the highest maximum operating temperature at 540ºC (1004ºF).

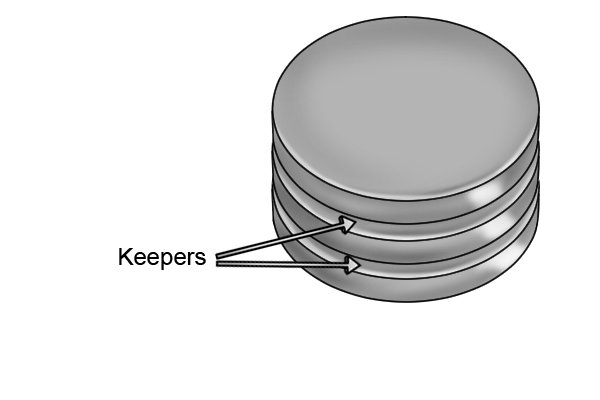

Store with a keeper

Store your magnet with a keeper on the two magnetic poles. A keeper is a piece of iron that is temporarily added between the north and south poles of a magnet to prevent it from demagnetising.

If a keeper is not provided with your magnet then store your magnets on a steel sheet.

Avoid electrical currents

Strong electrical currents in a close proximity to a magnet can cause it to demagnetise by disrupting the magnet’s magnetic field.

A strong electrical current causes the domains in a magnet to constantly change their magnetic alignment e.g. to face either the north or south pole. Each time the electrical current changes the alignment, a few of the domains do not move.

The longer a magnet is exposed to the electrical current, the more disorganised the domains become. Disorganised domains cancel out the magnet’s magnetism, causing it to demagnetise.

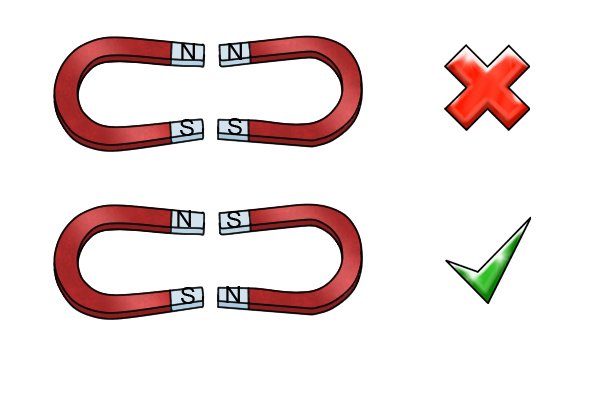

Store in pairs

Store magnets in pairs to prevent the two south or two north magnetic poles of the magnets from touching. Storing the magnets in pairs also helps to maintain their magnetism.

Keep magnets in a dry place

Magnets can corrode easily when stored in damp conditions which can affect the magnets' magnetism. The rust will create an air gap which stops the magnet from producing a secure bond on a ferromagnetic material.

If a magnet has started to rust but has not demagnetised, 400 grit sandpaper can be used to re-flatten the surface and remove any burrs from the magnet’s casing in order to reduce any air gaps which have formed.

To keep magnets dry, place them into a non-ferromagnetic closed container. This will also help to avoid the problem of the magnet attracting any unwanted metal debris.

Avoid damaging the magnet

For magnets without a casing, avoid dropping or knocking them against anything to prevent damage and demagnetisation.

Dropping or hitting a magnet causes it to vibrate. When this happens, the magnet’s domains randomise which causes the magnet to lose its magnetic field. This is because a magnet is created by having sections of aligned domains.

As a leading wholesale supplier and manufacturer of magnetic products, we are proud to offer high-quality NdFeB magnets to our valued clients. NdFeB, or neodymium magnets, are a type of strong permanent magnet made from rare earth materials, and are widely used in a variety of applications, from motors and generators to medical devices and magnetic jewelry.

Our NdFeB magnets are made to the highest standards, with advanced manufacturing processes and strict quality control measures, ensuring that they are reliable, durable, and long-lasting. We offer a wide range of shapes, sizes, and strengths to meet the specific needs of our customers, whether they are looking for small, lightweight magnets for their DIY projects, or larger, more powerful magnets for industrial applications.

In addition to our NdFeB magnets, we also offer a wide range of other magnetic products, including ferrite magnets, alnico magnets, and flexible magnets, as well as magnetic assemblies and custom-manufactured magnets to meet the unique requirements of our clients. With our extensive experience and expertise in the industry, we are confident that we can provide the best quality products and services to our customers, and help them achieve their goals with ease and confidence.

If you are looking for a reliable and trusted supplier of NdFeB magnets or other magnetic products, we invite you to contact us today and learn more about our products and services. We look forward to working with you and helping you achieve your business objectives.